Rudder blade thickness

|

|

I am making a new rudder for an Oughtred Whilly Boat. The rudder was lost in transit so need to buy rudder pintles and wood/ply.

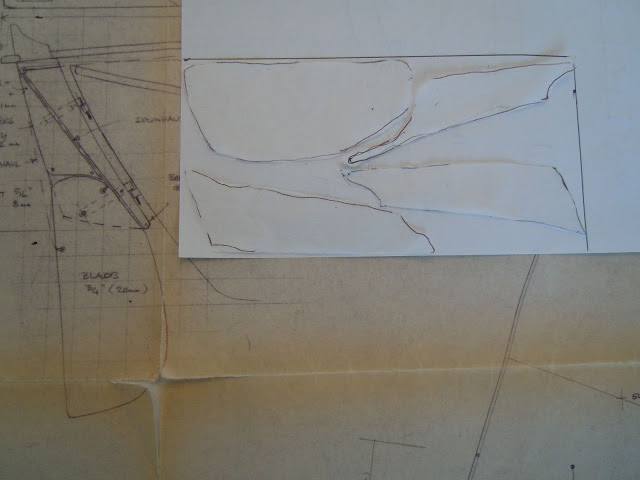

The gudgeons are probably Classic Marine and take a 9.5 or 10mm pin. Classic Marine pintles will cost over £100 just for two pintles. Barton make a simple pintle which also has a 9.5mm pin and they cost less than £10 each. It might sound odd to mix them but that is exactly what Swallow Boats have done with the rudder fittings on the Teifi Skiff. So if they can do it so can I. I had never even noticed till this morning when trying to sort out fittings. So, will use two Barton pintles. http://marinestore.co.uk/Barton_Rudder_Pintle_50mm.html Unless someone knows a source for lower cost 10mm pin bronze fittings. The Barton pintles are available in 35mm and 50mm sizes. So, what size rudder blades do people use? 35mm will mean basically, 12mm cheeks and 12mm rudder blade. 50mm will mean either 12mm cheeks, and 24mm blade. The plans call for 12mm cheeks and 20mm blade which does not fit the available fittings. I would like a lightweight rudder, ones I have made for Scows have been rather heavy. If a Mirror can use max 14mm for it's rudder blade, surely 12mm is enough for a little Whilly! 12mm does look very thin though. Perhaps 3 x 18mm taking 2mm off each cheek, so two 16mm cheeks, an 18mm core and an 18mm blade. Could just inset the pintles so they are flush with the rudder face. Brian |

|

|

Hi Brian

I just happen to have a set of Whilly Plans to hand. Iain specifies either a dagger-board or a centre-board. He also specifies the choice of a one piece rudder or a lifting/hinged rudder. I'd imagine the fixed rudder goes with the dagger-board but I don't suppose its obligatory. For the one-piece he specifies 3/4" hardwood or 2x 8mm ply. This would certainly be a lot lighter than the lifting rudder, and a lot easier to make. For the lifting rudder he specifies 12mm cheeks and a 20mm blade. I imagine the extra thickness of the blade is to give the pivot bolt something to bear on. Personally I would make the core 26mm and use old CDs as washers to prevent binding, a trick passed on by Phil Oxborrow. The 50mm pintles would then fit perfectly. Remembering that the Whilly Boat is designed to be a Beach Boat, so the rudder is likely to take quite a pounding and I wouldn't mess around with Iain's scantlings. Cheers Graham. |

|

|

Thanks Graham. I have ordered the 50mm pintles.

Will make the lifting version. I usually use plywood for rudders, it makes shaping the blade very easy. Might be nice to use solid wood this time though. The Whilly Boat is coming along very nicely. All brightwork and the hull interior were soaked in Deks Olje D1 when built a long time ago. Just needed a surface clean up and re-coat. Very impressed with D1. There was no sail either with the boat and had huge good fortune, thanks to the seller telling me about it, to buy a lovely James Lawrence Whilly Boat sail which they had in stock. Very soft handle, flat non shiny finish, leathered corners, 8oz cloth but so soft. Brian |

|

|

Our Wayfarers use 18mm lifting blade and 18mm cheeks with the pintle straps in a recess. Seem to stand up to the stresses of a teaching boat OK.

If you were going to glass the blade I'd use thinner ply (16mm?) and put spaces between the cheeks and filler piece, but YMMV Simon |

|

|

MilliBee's new centreboard is 18mm (like her rudder) so I'm glad the WF is similar! John suggested I glass the board to improve its strength.

Laminated 2x9mm ply is very strong - 3/4in hardwood will cost a small fortune. -Paul |

|

|

I always glass centreboards, usually with uni-directional cloth, but normally leave rudder blades without glass.

When re-furbishing a Cornish Cormorant, I was aware that a friend had broken two blades when out in extreme conditions. They failed at the exit of the cheeks and when I looked there was a gap between the blade and the cheeks which meant all stress loads were concentrated on the edge of the cheeks and this was indeed where the blades snapped. Fortunately there was room for a layer of unidirectional cloth on both sides of the blade. Fits much better now and much more confident it will not break. Here's a couple of pics of the Whilly Boat after finishing coating in D1 on Monday.   Brian |

|

|

This post was updated on .

Looking at materials, cannot quite cut the whole rudder and stock from a 1/4 sheet. So a half sheet will cost £126 in mahogany and £64 in ocume.

Just rang a local supplier, Mison in Ringwood, and they can do an iroko plank 10' long, 1" thick and about 9" to 10" wide for £40 plus vat. Looking at the components it should just be possible to cut out the two cheeks, infill and blade. Slightly narrow for the blade so that could be laminated. Will see what Totton Timber have in stock. They stock sapele 25mm x 300mm at £17.25 per metre plus vat. A solid timber rudder would be very nice and suit the boat in that it can be soaked in D1 to match the rest of the fitting out. Does this equate to rudder building experiences of forum members? Brian |

|

|

I made the rudder for my Acorn from iroko. Think it was four planks butted together, I did use biscuits in the joints to keep them aligned. Better made of several sections laminated than one big plank I think. I have found Iroko is among those woods partiularly inclined to bow as it dries (still have one length that is now distinctly S shaped) so, in addition to laminating to stabilise it, it's worth picking your plank carefully if you don't have spare thickness for planing it flat.

That rudder has stood up to strong winds and abuse in transit very well though the Acorn doesn't carry as much asil as other Iain Oughtred designs. Tim. On 7 Feb 2013, at 12:33, BrianP [via UK HBBR Forum] wrote: Looking at materials, cannot quite cut the whole ruder and stock from a 1/4 sheet. So a half sheet will cost £126 in mahogany and £64 in ocume. |

|

|

Thanks Tim, my son Ed has just popped by and he mentioned the plank twist with iroko issue as well.

Began to think perhaps stick to ply for the blade and fill piece and hardwood for the cheeks if I can buy small lengths as listed by Totton Timber. So, thinking about a quarter sheet of 18mm ply for the blade and fill piece. Thought it best to make paper patterns to lay out on a scale 1/4 sheet of ply and realised that the pieces can actually have a fair amount of overlap if laid out narrow end to narrow end and that I might be able to get all the components out of a 1/4 sheet. Looks like I can. So can choose to have all mahogany ply, ocume core and blade with hardwood cheeks or all laminated hardwood.  Brian |

|

|

Laminated hardwood is actually better than ply if you can manage it - the lamination joints run across the thickness of the blade not along its chord. Usual practice is to cut laminates from a single plank and then reverse every other one so the tendency to twist cancels out.

With plywood, only half of the wood is doing anything to resist bending (the plies where the grain runs vertically). The "horizontal grain plies" are just packing. With solid wood laminations, all of the grain runs vertically, and is working. The hardest bit in my experience is getting the blade to stay flat whilst gluing it up. You need not only sash cramps to hold the laminations together, but also a framework to stop it bowing under the pressure. Simon |

|

|

'afternoon all -

The Whilly came north last year, I took it on from Brian as one of the magazine in house boats. I'm in the process of recommissioning for the summer and am currently fitting a floor. Last season she was used as a rower because we hadn't completed the rudder. I used some float bags for buoyancy as Kielder where she is sailed is a large and sometimes malevolent place where the weather can change very quickly - this is down to altitude which is around 1000 ft. I'm currently rubbing down with deck ojl D1 - very fine steel wool dunked in the ojl appears to work quite well. I've also fashioned a floor with some douglas fir I had left over. Because the boat will live outside for 8 months a year and the canvas cover no longer fits absolutely perfectly I am mounting a bronze drain club in the bilge, even a month away can result in 6 inches of standing water. and that is through a 3 inch square hole in the canvas cover (at the end - although I do mount another tarp over the boat the horizontal rain at Kielder gets in. ) I am seriously considering adding two decked buoyancy boxes fore and aft. I suspect the chap who originally built the boat was a builder rather than a sailor and it would look a lot better than large yellow inflatable sausages. However, time is getting tight with Beale Park on the horizon and Mik Storer's OzGoose to complete before then. I suspect that this won't happen this year and we will be using the bags again. I am also considering 50 kilos of ballast either side of the centreboard housing. She's very twitchy under oar - gawd knows what she'll be like under sail! So the rudder issue continues - I've got several rudder blades that could be suitable and an oak stock with bronze fittings which will need to be taken to bits and reassembled with a wider gap as the current blade is a kidney shaped steel one. |

«

Return to Builds in Progress

|

1 view|%1 views

| Free forum by Nabble | Edit this page |