Trailer Improvement for launch/recovery

|

Paul H (admin) |

Trailer Improvement for launch/recovery

|

|

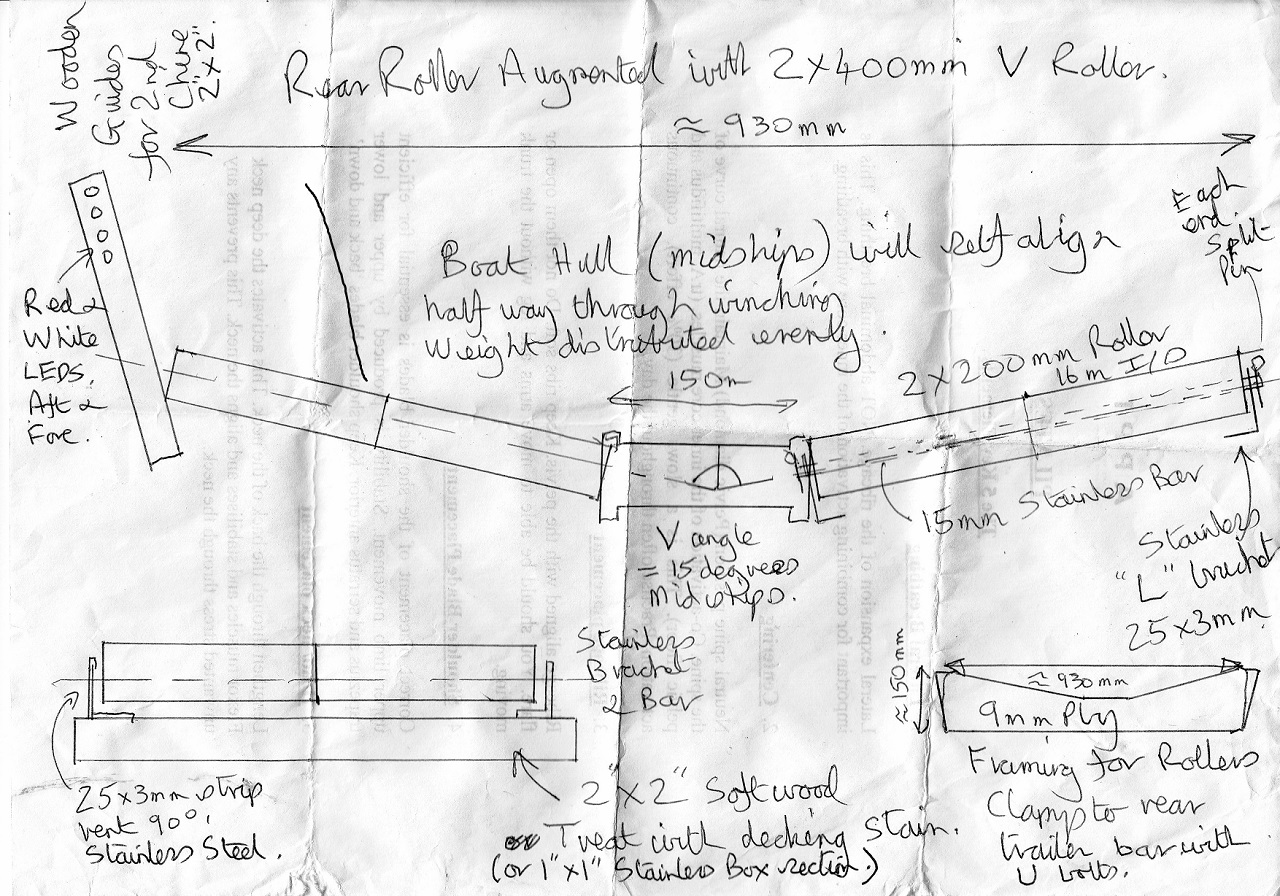

Here is my design sketch for a trailer improvement that will fit at the back of a standard trailer, slightly behind the rear bow roller. It is designed for a typical home built plywood dinghy which might have 6mm curved/twisted panels, a V section bottom and at least one chine. Clearly the loads must be spread over a large area - so more rollers is good. It is also designed for single handed use where it may be impossible to keep the boat perfectly aligned with the trailer due to tide, wind and waves.

The assembly matches the midship shape, as this must pass through when winched in 50%. The theory is that a combination of gravity and the rigid shape of wide rollers and wood side arms will ensure the keel eventually rolls on the rear bow roller, even if winched at an angle due to tidal flow. The wide rollers also keep the boat upright from about 30% to 60% winching. Beyond 50% winching these rear rollers will have less and less effect, eventually they will not touch the boat which will eventually sit on the rear bow roller and be pulled/twisted to sit on the 2nd and 1st bow rollers. Heavier plywood boats designed for coastal cruising often have a central hog and bow rollers conveniently support the entire boat weight, as the hog is the strongest part of the hull. MilliBee's hog for example is two lengths of 4in x 1in running the entire length of the hull. They are laminated with epoxy and screwed - the keel then becomes incredibly strong. Logically a similar assembly could fit midships. This has 2 uses: first to force alignment of the keel on the 2nd bow roller, second to provide excellent support of the boat whilst towing. Its mostly inspired by recovering MilliBee, when I realised any supports must allow the low angle V section at midships through and not place point loadings on the 6mm hull panels (although its not impossible to strengthen the panels internally) The LED lights are legally required, because the short wooden arms will be wider than the hull. Hence they must be white at the front and red at the rear. They also make inspection of the wheels at night much easier! What do you all think of the Mark 1 design? Paul PS: metals4u.co.uk are very reasonable for aluminium and stainless strip or tubing. In fact a 2 1/4in wide aluminium tube, thickness 1.6mm or 16 guage is £29 for a 4 metre length. |

|

Paul H (admin) |

Re: Trailer Improvement for launch/recovery

|

|

One user said he can't see the sketch on a Ipad.

I can see it on my Samsung phone and Android 7in tablet. Do other Ipad users have a problem seeing the sketch? Edit: You can view the picture with this link. http://uk-hbbr-forum.967333.n3.nabble.com/file/n4029092/IMG_0003_1280pix.jpg Paul |

|

simplesimon |

Re: Trailer Improvement for launch/recovery

|

|

In reply to this post by Paul H (admin)

Richard Harvey, when he built his trailer for his GIS, instead of hard rollers used soft boat fenders, the type with a hole down the middle, through which he put a bit of steel rod to act as an axle. For an application like this they would probably spread the load enough.

Simon |

|

Paul H (admin) |

Re: Trailer Improvement for launch/recovery

|

|

Simon,

Ahh..I never knew centre hole fenders existed, and yes they are ideal to nudge a plywood hull in the right direction. Thanks. They are also very flexible on a small boat. Sometimes you need a continuous length of horizontal fenders which centre hole types could provide quite easily, cleat one rope hard and job done. Lowering through a lock for example. But other times we need them hanging down individually. The hard rollers should allow the bow to hit rubber anywhere in a 3ft window. Then hopefully be winched in correctly. It's hit and miss at the moment and there are a few paint scratches on the metal cross member! Paul |

|

simplesimon |

Re: Trailer Improvement for launch/recovery

|

|

Google "Polyform HTM fender" to get the idea. I suspect there are other makes. S |

«

Return to General Discussion

|

1 view|%1 views

| Free forum by Nabble | Edit this page |