Building a little sailing dinghy

|

|

I used to sail Moth and Cherub dinghies in my youth but for some time have had it in mind to get a little una-rigged dinghy to potter about in.

I used to have a little thing called a Poole AB but found it was too heavy to car-top, so decided to build something lighter. After I'd looked at the available kits, and picked myself off the floor after seeing the prices, I looked at plans for soething about 9 feet long, but most were for flatties or glued clinker. I'm wanting something that will sail better than a flattie but is easier to build than glued clinker, so I decided to design a simple hard-chine boat and see what was the most boat I can get out of 2 sheets of plywood, using stitch-and-tape. I acquired an old Mirror mainsail, and then a complete mast/boom/gaff from boat jumbles, and some cutoffs of 19mm ply for the rudder and daggerboard. So I've started and have all the panels cut, but have one little problem..........all my Moth building experience was with 3mm and 4mm ply which bends easily, but when I try to twist the forrard ends of the 6mm bottom panels to get the lower part of the stem, it doesn't want to go. Hoe effective is soaking the plywood? Hot water? Boiling? Hot towels? Hairdryer applied carefully? Can anyone give me the benefit of their experience as to the best way to do this? Making partial slits in the ply is the other possibility, but I'm worried about going too far, and I'm not sure which way to run the slits in relation to the direction of twist. So if anyone can help, I'd be grateful. Hopefully after this weekend I'll have a few photos to post if anyone's interested. Paul |

|

tony waller |

RE: Building a little sailing dinghy

|

|

Torturing ply : on a couple of boats I built I used a towel, wrapped around the part that had to be twisted, poured boiling water over the towel, then wrapped all that with bubble wrap as insulation. It worked very well. Good luck. Tony |

|

|

Hi Paul. I'm with Tony. Wrapping in towels and soaking in boiling water has worked for me. I used tin foil as an insulating wrap, but only because I never thought of bubble wrap! Once used the hose from the wallpaper stripper boiler to direct a steam jet onto an awkward piece. Worked well enough but it took a while to soften the ply and the temperature was high so I got nervous about the glue so I haven't repeated the experiment. Look forward to seeing pictures and, in due course, the finished article. Tim. From: "tony waller [via UK HBBR Forum]" <[hidden email]> Subject: RE: Building a little sailing dinghy Torturing ply : on a couple of boats I built I used a towel, wrapped around the part that had to be twisted, poured boiling water over the towel, then wrapped all that with bubble wrap as insulation. It worked very well. Good luck. Tony

|

|

|

In reply to this post by Paul M

Welcome to the forum.

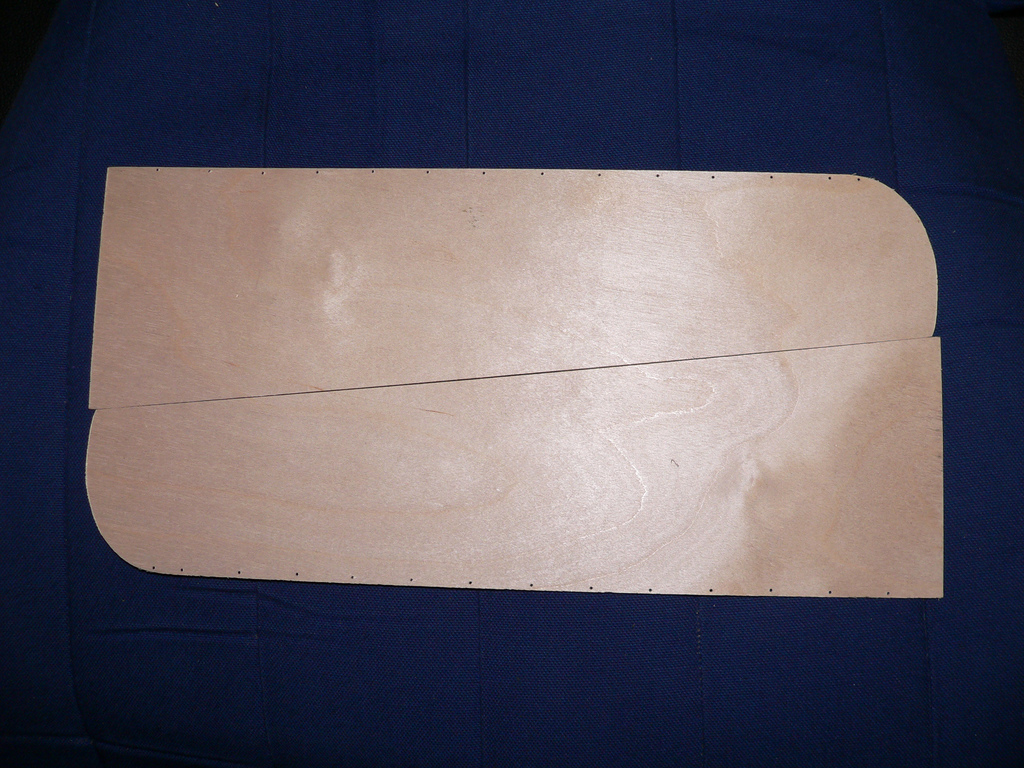

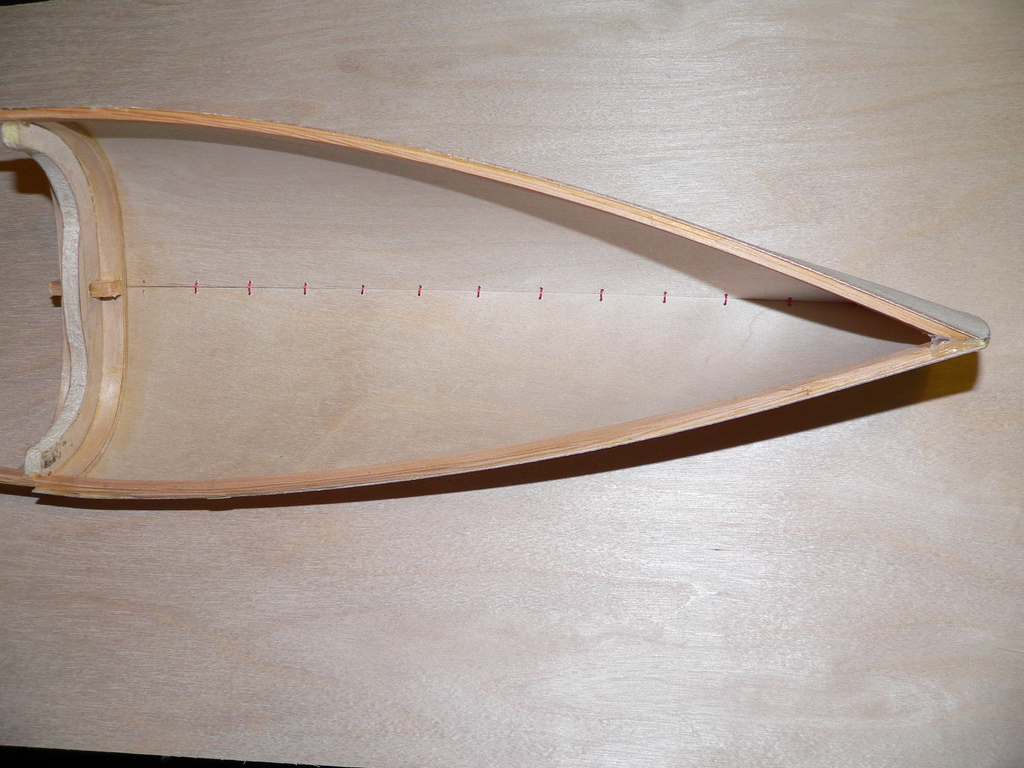

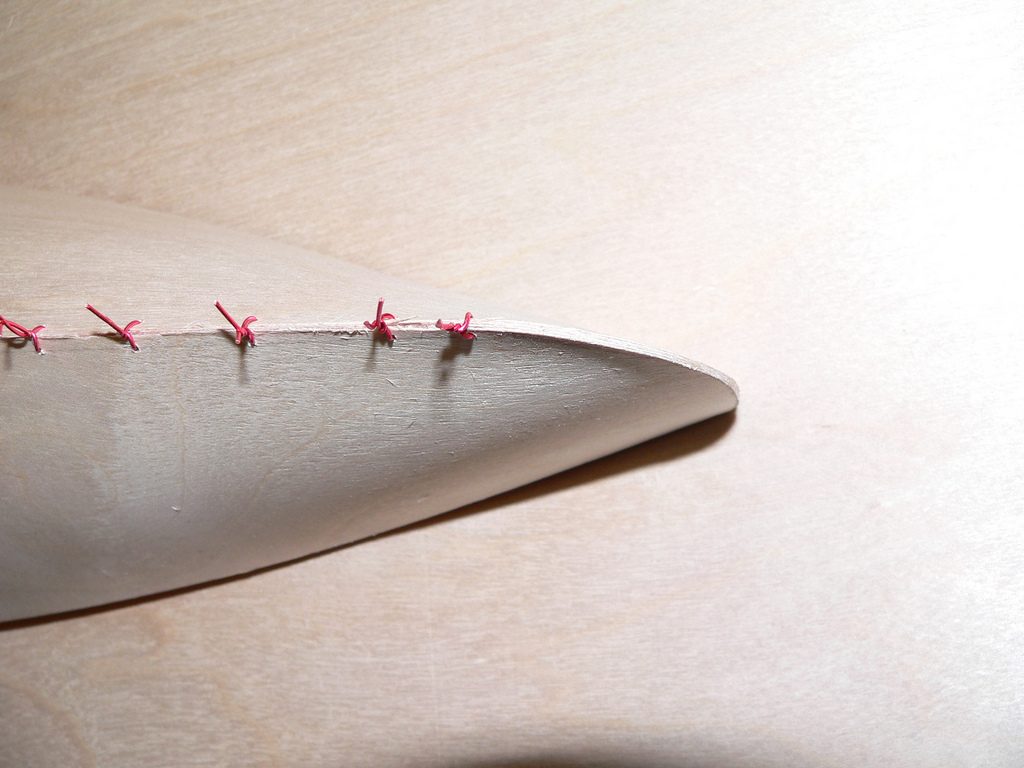

I did a lot of experiements with torturing ply when I was first looking at designing and building a hull for my electric boat (I ended up buying a Winsome hull from Swallow Boats). What I found was that tortured ply doesn't really have much of a 3D bend in it, even though it looks as if it does. More often than not what it does is use sections of a cone to create apparent 3D shapes. Here are some photos of models I made when trying out some ideas:  First, I started out with a scale "8 x 4" sheet and tried not to waste any wood (a bit like Chris W with Octavia). This was for a canoe to start with, so these two bits represent half the hull.  Heres a shot after stitching these two bits of ply to shape, with a central bulkhead to give the right shape amidships.  This shot shows the bulkhead a bit better and also shows the inner gunwale strips I added to give some shape to the sheer (the sheer maturally develops from the ply shapes shown earlier).  This close up shows the shape that the bow adopts after a little persuasion. In reality these bits of ply are still only bent in 2D, except for the bit where I tried to force them to adopt a 3D curve at the central bulkhead.  This was the finished model, with strips added for a sole (and to stiffen and flatten this area). It looks OK inside, but outside this method tends to produce a bump right on the centre bulkhead, where the ply doesn't want to bend into a 3D shape. I modified this hull shape into a shape rather like a slipper launch:  I wasn't very happy with the way the centre turned out, so didn't take this idea further. One thing I did discover was that ply doesn't like to stretch, but it doesn't mind compressing a bit. When trying to torture it into 3D it's the inside face that needs to be steamed or kept wet with hot water, rather than the outside face. Have you seen some of the free tortured ply plans that are around? I have files with photos and plans for the old Tornado catamaran hulls and also a tortured ply canoe that may be of interest. The total size is around 17Mb for the Tornado and 5Mb for the canoe, so I could email the to you fairly easily if you wish. Jeremy |

|

Port-Na-Storm |

Re: Building a little sailing dinghy

|

|

In reply to this post by Paul M

Hi Welcome to the Forum.

I'd be interested whether you design by intuition or if there is any science involved. Either way its good to see another forumite designing their own boat. I'd agree with the suggestions others have made regarding the torturing of plywood, you could also try playing it any of Barry Manilow's records. That should do the trick. If the 6mm just refuses to go consider two layers of 3mm. Photos please, Graham |

|

|

Flo-mo has been creating some very neat boats using one and two sheets of ply. All his plans are free. Here are some pictures of his tortured ply kayak that may help

http://flo-mo.weebly.com/compounded-plywood-kayak.html Brian |

|

|

Maybe this can help you:

When buildingt my little Thames skiff, I used a method from Jordan boats/Selway Fishers DVD: Some metal wire and a stick and SLOWLY twisting untill it gets in. I used towels and boiling water as well. Especially the stern with its wine glass transom needed something like that. Its 5mm 5 ply. Bow:  stern:  |

|

|

Over here, Anders, we call that arrangement of twisting a wire (or rope) with a stick a "Spanish windlass". Seems very appropriate for you to have used it to build a boat in Spain. Jeremy |

|

|

In reply to this post by Anders

In order to get fine ends like those shown in the photos to bend,it is helpful to leave tabs of waste material above the cut.

Doing this gives you leverage to bend the material to shape. Neil Barratt, Cornwall, UK email :- [hidden email] Date: Sat, 27 Aug 2011 09:43:30 -0700 From: [hidden email] To: [hidden email] Subject: Re: Building a little sailing dinghy Maybe this can help you: When buildingt my little Thames skiff, I used a method from Jordan boats/Selway Fishers DVD: Some metal wire and a stick and SLOWLY twisting untill it gets in. I used towels and boiling water as well. Especially the stern with its wine glass transom needed something like that. Its 5mm 5 ply. Bow:  stern:  If you reply to this email, your message will be added to the discussion below: http://uk-hbbr-forum.967333.n3.nabble.com/Building-a-little-sailing-dinghy-tp3287031p3289317.html To unsubscribe from UK HBBR Forum, click here. |

|

|

In reply to this post by Jeremy

Jeremy

Things have many names. I´ve never seen a Spanish Windlass in Spain. And I´ve been here 10 years. A good example,: What you call a adjustable or universal spanner is called a llave inglesa (english key) in Spain. In Denmark its called a Svensknögle (Swedish key)

|

|

Chris Partridge |

Re: Building a little sailing dinghy

|

|

I rather fear that it is called a Spanish windlass in England because it looks like the classic Spanish method of capital punishment, the garrotte.

|

|

|

In reply to this post by BrianP

Nice work! Gavin

From: BrianP [via UK HBBR Forum] <[hidden email]> To: gmatkin <[hidden email]> Sent: Friday, 26 August 2011, 20:58 Subject: Re: Building a little sailing dinghy

Flo-mo has been creating some very neat boats using one and two sheets of ply. All his plans are free. Here are some pictures of his tortured ply kayak that may help

http://flo-mo.weebly.com/compounded-plywood-kayak.html Brian If you reply to this email, your message will be added to the discussion below:

http://uk-hbbr-forum.967333.n3.nabble.com/Building-a-little-sailing-dinghy-tp3287031p3287849.html

To unsubscribe from UK HBBR Forum, click here.

|

«

Return to Builds in Progress

|

1 view|%1 views

| Free forum by Nabble | Edit this page |