How to cut an aluminium mast in 5 seconds

12

12

|

Paul H (admin) |

How to cut an aluminium mast in 5 seconds

|

|

On the run down the main channel near Cobnor CW and myself noticed more than the average amount of mast bend on MilliBee. A scary amount in fact, so it was obvious she needed a stronger mast. I decided to cut my old aluminium Enterprise mast down to replace the (weak) wooden mast from the Vagabond rig.

Evolution tools specialise in metal cutting. Their Rage 3 sliding saw comes with a blade that cuts wood, 6mm mild steel and everything in between. So I gave it a go: A really clean cut, just above shrouds plus area to mount a mast light, antenna etc. I'd appreciate some advice chaps on the Gaff jaw size of 58mm which bends out to about 62mm. The mast is 68mm x 58mm so at certain angles the Gaff will jam. Do I simply widen the jaws a bit or will the oval mast shape cause problems? Also will the pointed sail track wear into the Gaff too much? (reverse the mast perhaps?)  cheers Paul |

|

|

You could grind the groove/fairing wings off the back of the mast section, perhaps just in the upper zone where the gaff jaws would normally sit while sailing. This would leave the mast with a slightly concave back in that area, and reduce the cross section's long axis allowing the gaff jaws to turn more freely.

Maybe try it first on an offcut to see if it helps! The stiffness of the mast in the lower and mid-height areas would be unaffected. |

|

simplesimon |

Re: How to cut an aluminium mast in 5 seconds

|

|

In reply to this post by Paul H (admin)

My instincts say

a) reverse the mast, so that, when sailing closehauled and maximum pressure is on the gaff jaws, you have a round smooth surface to bear on b) widen the gaff jaws so it doesn't bind at any angle. You may want to put foam pads to cut down rattling. I'd be very wary of cutting down the section. Just my two penn'orth Simon |

|

Paul H (admin) |

Re: How to cut an aluminium mast in 5 seconds

|

|

I decided grinding the aluminium was too difficult and risky - I would prefer to spend the time producing a new wooden mast.

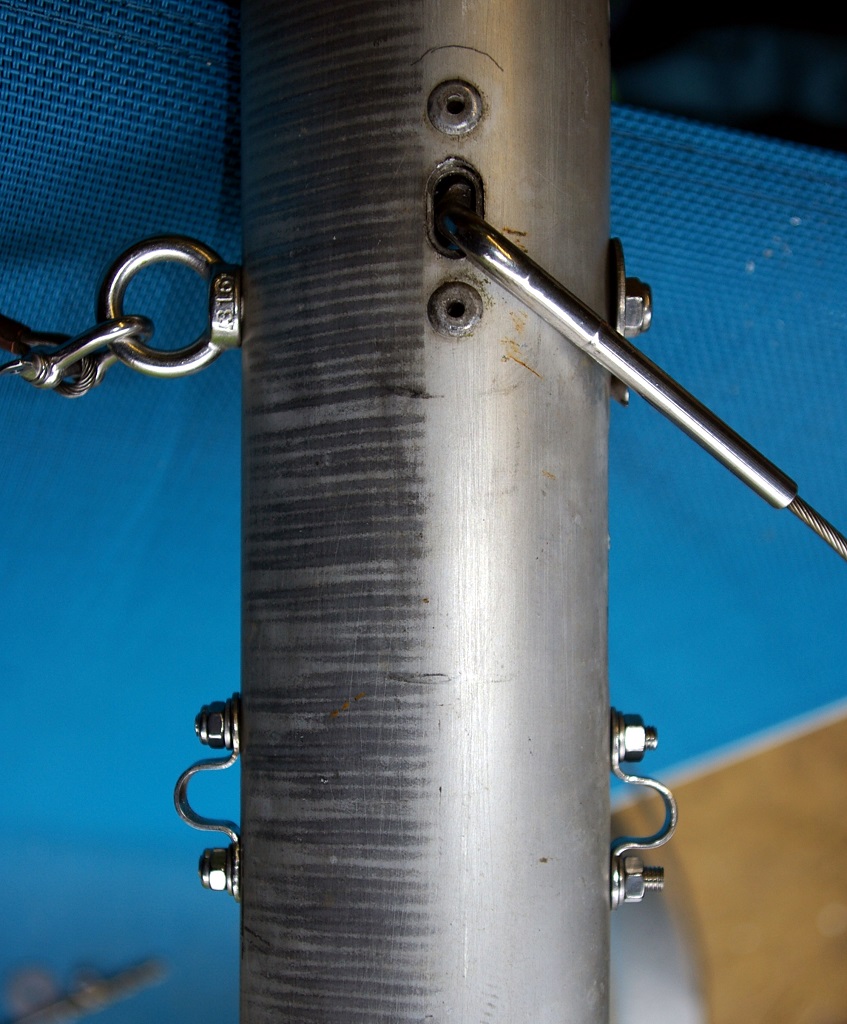

By carefully drilling an access hole next to the original forestay hole (on the left) I could easily remove the forestay:  Then I drilled the hole through the other side to fit a 6mm ring bolt for the forestay - effectively reversing the mast as Simon suggested. Then the holes for the jib deck eye where drilled through so that I could attach another deck eye the other side. The result is the new forestay position on the left, the shrouds easily rotate to the back and peak/jib blocks can be supported. Hence the Gaff jaws now move on the mostly-circular side of the extrusion:  The (widened) jaws will always bear on a curve, the bulge just moves left or right a little and the jaw taking most load still bears on an arc at the same point as a circular mast. The eagle-eyed will notice the swaged shrouds have to swapped, they come in port/starboard pairs! When everything has been tested I will Loctite all the threads. cheers Paul |

|

|

Looks a good arrangement Paul. Just as an alternative approach, the way I did this was to have the mast swivel on a pivot at the base, as do the masts on most racing multihulls. This means that gaff jaws are not needed, there can be just a slider at the bottom of the gaff which runs in the mast groove or track and the gaff (yard?) always lines up with the back of the mast so I think you get smoother airflow over the mast, gaff and the luff of the sail. This has worked well for me since I first launched my boat in 1978.

I agree that many hand held power tools work well with aluminium alloys. Carbide tipped tools are good for this. At one time I worked in a factory that did a lot of work with ally and although most of our ally parts were made on CNC milling machines it was quite often necessary to make adjustments using hand held tools, often on completed assemblies and sometimes 'on site'. A method that worked well was to apply 'Boelube' to a coarse disc in an angle grinder, this allowed rapid shaping of ally without the disc getting clogged up with aluminium. Boelube is a white wax like substance, I think supplied by Boeing aircraft company. I havent seen Boelube in any high street retailers so I wonder if there is an alternative that would be available for DIY, does anyone know? Another point is that it is good to apply a corrosion inhibiting paste wherever stainless steel comes into contact with ally in a marine environment. Without this there will eventually be corrosion of the ally. One product is a yellow paste called Duralac, I got a tube from an on-line chandler. Ideally the ally would be electrically isolated from the stainless with plastic washers etc. but this is not really practical for an assembly such as in your photos. Good to see you all at Cobnor. Alastair, Cliff, Josephine and myself extended Cobnor by sailing over to Bembridge and back. We did a bit of exploration on foot around Bembridge harbour and had a nice evening in a pub. Coming back, Cliff set off earlier than us and made it into Langstone harbour just fine. Alastair also went into Langstone but had difficulty entering against the tide and we made a real mess of it going into Chichester and getting becalmed on the wrong side of the sand banks, but we eventually rowed up the harbour with flat calm in the rain to meet with Alastair at Hayling bridge just as darkness fell. We all met up with Len and Sarah for a nice coffee time in Emsworth the following morning day. |

|

Paul H (admin) |

Re: How to cut an aluminium mast in 5 seconds

|

|

This post was updated on .

Thanks John,

The rotating mast is a clever idea, exactly what windsurfers did. Rotational Asymmetric Foil (RAF) sails with 5 or 6 full length tapered battens became universally popular in the mid 80s for windsurfers. The luff tube was rotated by batten tension (one strap per batten) to produce a wing shape on each tack. Along with high downhaul the wing shape held well in strong gusts - its critical the centre of effort stays between your hands or ideally between the rope harness on the boom. Later camber inducers where added - a circular jaw and long stiff arms that fitted inside a batten pocket of a wider luff tube. They further enhanced the wing profile by producing a smooth surface on both sides of the wider luff e.g. not asymmetric. They were harder to rig and use, but every serious racer used them. It's a shame only multihulls have benefitted from all that R&D. I'm hoping to get the new mast ready for the DCA South West Salcombe meet, weather permitting. I now have to trim the final length at the bottom. The wooden mast was extended to just over 13ft to accommodate a large Wayfarer genoa. As if by magic the Selway Fisher main mast length on the Lynx 14 is 13ft 3in. That's so all the spars can fit into the hull when towing. With the old mainsail she went like a train, the gaff could go higher for a bigger sail, so I don't really need the full 14ft 6in of the ally mast. I need to do some quadruple checking of lengths! cheers Paul |

|

Chris Waite |

Re: How to cut an aluminium mast in 5 seconds

|

|

In reply to this post by John P

Your rig, John

I've had a vague search around for photographs and can't find anything even showing the whole main actually set. (How vague can I get?) I am under the impression your boat is gunter rigged, yes? Questions: 1. What section is your mast? 2. Do you use a separate throat halyard? 3. If not, how do you reef? 4. You say the mast rotates, does the gooseneck pivot laterally, as well as vertically, or do you rely on the boom to do the mast rotating for you? 5. A rotating mast would require that all the stays come off a single point at the head of a gunter, or on the forward edge of a multihull wing. If not then rotation would tend to wind the stays round the spar like the very beginnings of a Maypole and increase the tension in them, forcing the foot downwards; yes? 6. Do you feed the luff of the main, after the gaff/gunter slide, into a slot on the back of the mast, or is it laced? 7. Similarly, is the head of the sail in a slot on the yard, or is it laced? 8. Any pictures? Thanks Chris W |

|

|

This post was updated on .

In reply to this post by Paul H (admin)

Hi Paul

Look forward to meeting up at the Salcombe DCA meeting on Saturday September 12. You have a longer journey than we have, so if you are launching at Batson Creek slipway and can let us know when you expect to arrive we should be able to meet you there to help launch Millibee. As indicated in the DCA magazine, the plan is to gather at the head of Frogmore creek that afternoon (HW 18:17). Assuming that things havent changed since a couple of years ago, there is a public pontoon for mooring at Frogmore and we can tie up to this overnight. The Globe pub provided us with a nice meal last time we were there. Re rotating masts, it is of course the luff sleeve of the sail that rotates around the mast of a windsurfer, the mast does not rotate relative to the hull to any significant extent. And I think it would be true to say that rotating masts were used on multihulls before windsurfers had been invented. Re cutting spars to length - easy to cut a bit more off if too long, adding a bit is another matter - but I am sure you are aware to that! If your mast and yard extend a bit too high you can always have a bit of string between the top of the top of the sail and the top of the yard, at least on a temporary basis. Indeed we have been sailing around like that all season since the damned sailmaker made our mainsail about 250mm too small, despite being given the old sail to measure. Also delivered the sails 12 months overdue. We had said we were planing to sail to Holland and without telling us they put red, white and blue horizontal stripes on the sails - could have been intended as a built in courtesy flag - but unfortunately they got the arrangement of the colours upside down! When we actually did sail to Holland locals were not slow to point this out to us. |

|

|

In reply to this post by Chris Waite

Hi Chris

Our boat is gunter rigged in light winds and bermudian rigged in stronger winds. When it is bermudian rigged the yard is stowed on the floor of the boat with one end of it in a 'tunnel' built into the forward bouyancy tank. This saves some windage and weight aloft in strong winds but of course it takes longer to reduce sail than just reefing. Both the bermudian and gunter sails have cringles for one reef. Taking a reef in the gunter mainsail is our first step down in sail area, changing to the bermudian sail is the second, removing the jib from the bermudian rig is the third. We have never yet tried reefing the bermudian sail although there are cringles to do so - I think that ultimately the waves become the limiting factor for a small boat on the open sea rather than the wind alone. 1. Mast extrusion was an off-cut from a mast maker that has long gone out of business - I think it was called Bowman Spars. It fairly similar to the one Paul has just shown us except that the fore and aft dimension is more nearly equal to the lateral dimension. The boat was built with an aluminium mast and wooden yard and boom. Two of the few changes made since the boat was built were to change from a wooden yard to an aluminium one, then quite recently to change from a wooden boom to an aluminium one. 2 No 3. We have two points on the yard at which the single main halyard can be attached, so we always lower the yard into the boat to reef, generally allowing the boat to slowly reach allong under jib while reefing. We loose more ground to windward than we would if we were to reef with the sail set but we have got used to doing it that way. The single main halyard minimises the number of ropes to get tangled up and probably reduces windage a bit, I have avoided having a topping lift for the same reasons. To avoid rope tangles and save windage I am a bit reluctant to even set up the flag halyard to hoist all the pretty flags that Josephine is so fond of! 4. The gooseneck allows the boom to swing up and down and from side to side, as do goosenecks on most other boats. The gooseneck attaches into the groove at the back of the mast and can slide up this groove to any height which is usefull for setting up the tent. The gooseneck is an unusual design using car seat belt webbing to make the hinge, but to save bits and bytes I wont go into the details right now. 5. Yes, the stays all attach to the front of the mast, as with the rotating masts on nearly all small multihulls (but not on the big French trimarans). If the stays were tight and there were absolutely no elasticity in anything this would prevent the mast rotating, but in practice the mast does rotate automatically to about the right angle. The lower end of the kicking strap is attached to a short arm fixed at the bottom of the mast and this helps prevent the mast rotating too far. 6. The luff of the mainsail below the bottom of the yard is linked to the groove in the back of the mast by a few small plastic sail slides. This works because the mast rotates, it might not work so well otherwise. 7. The top part of the gunter mainsail slides into a groove in the back of the yard. The alternative might be to have the yard fitted into a sleeve sewn to the luff of the sail, with a cutout in this sleeve so that the main halyard can be attached to the yard. I dont think I would want to have a lacing for this purpose, that would be rather fiddly I think. 8. No, but I do mean to some day write this up with pictures, perhaps for the DCA magazine. Lots of questions, but thats OK. John |

|

Chris Waite |

Re: How to cut an aluminium mast in 5 seconds

|

|

Thanks for the detailed information, John

Lots of questions, yes – I don’t know which of us has been further under sail, but you and Mistress Josephine have almost certainly survived the lion’s share of dinghy cruising. As that has almost all been in the same boat, you are obviously doing something right and it behoves me to fully appreciate your methods. I am not above learning a thing or two. 3. Interesting that you reef in big, beautiful chunks and I’m with you on that. I note both you and Cliff (Martin) are wary of stuff aloft and I do agree with you, a lot, though I find allowing myself a topping lift on an unstayed mast provides a degree of control that is most convenient for reefing, close quarters and the unexpected, that I am prepared to sacrifice three 4mm lines to the masthead. And that’s just the little-one; being able to drop the gaff main on TW between lifts and lazyjacks, into a top-opening cover, is of the essence. Come and try them? 1. The mast sounds equivalent to the old ‘D’ section Proctor mast. 2. Throatlessness, yup; otherwise there’s no point in having a gunter. I have an old wooden lifeboat mast on Tit Willow and the one on Polly Wee is the remnants of a whaler sweep. However both booms are salvaged from other alloy masts and the yards from an alloy lateen rig and a carbon fibre windsurfer mast respectively. 4. I was interested in the gooseneck because if the sail is used to turn the mast, it needs to be fixed laterally like the Finn dinghy, but your kicking strap on ‘a short arm’ (like many multihulls), explains how it works. I was once given the opportunity to race a trimaran from Dubai to Muscat and spent a week or so beforehand setting it up. This included installing a large bar like structure at the base of the mast – like Frankenstein’s neck bolt, in order to rotate it manually at each tack. 5. How do the big French trimarans allow the mast to rotate – perhaps a central connection within the mast, maybe even spread to the skin of the wing by some triangular internal structure? 6. Are the slides captive using a gate of some sort, or do they drop out of the track on lowering the sail? 7. On an alloy yard with a cross section that includes a groove, that has to be the best way of holding it and the sail in proximity. Somehow a sleeve with cut-outs doesn’t seem as effective. 8. I’m looking forward to the article and pictures Chris W |

|

Paul H (admin) |

Re: How to cut an aluminium mast in 5 seconds

|

|

In reply to this post by John P

John,

We haven't finished the reefing yet and with gusts of 35km/hr forecast inland I don't think its wise to attend Salcombe. I haven't fitted the new mast/shrouds either. We might get it all done today except we are currently at the top of Chosen Hill (510ft). The weather was too good to skip a nice walk in the warm sun. There was an Iron Age fort here with views over 40 miles to Wales in the West. 20150911_123432.jpg Regards Paul |

|

|

Hi Paul, well it worked out quite well, we stayed in the estuary and the wind was not too strong, but flukey with the hills all around. It was sunny on Saturday and we were back home before the rain started today (Sunday). Frogmore creek is attractive and at the head of the creek there is a very handy public pontoon where we moored overnight - see pic. The Globe Inn at Frogmore provided a nice meal for us, as last time.

The mention of Chosen Hill prompts me to ask if there is a possiblity of another HBBR rally on the River Severn some day. John |

|

alopenboat |

Re: How to cut an aluminium mast in 5 seconds

|

|

Yes Paul, you missed a good one.

Saturday morning was challenging but not overly so as we decided to stay in the estuary. The afternoon run up to Frogmore was so relaxing that Josephine nearly fell asleep at the tiller. This morning was sublime. On 13 Sep 2015 at 10:25, John P [via UK HBBR Forum] wrote: > > > Hi Paul, well it worked out quite well, we stayed in the estuary and > the wind was not too strong, but flukey with the hills all around. It > was sunny on Saturday and we were back home before the rain started > today (Sunday). Frogmore creek is attractive and at the head of the > creek there is a very handy public pontoon where we moored overnight - > see pic. The Globe Inn at Frogmore provided a nice meal for us, as > last time. > > <http://uk-hbbr-forum.967333.n3.nabble.com/file/n4029097/P1200186.jp > g> > > The mention of Chosen Hill prompts me to ask if there is a possiblity > of another HBBR rally on the River Severn some day. > > John > > > > _______________________________________________ > If you reply to this email, your message will be added to the > discussion below: > http://uk-hbbr-forum.967333.n3.nabble.com/How-to-cut-an-aluminium-mast > -in-5-seconds-tp4029065p4029097.html To start a new topic under > General Discussion, email [hidden email] To > unsubscribe from UK HBBR Forum, visit > http://uk-hbbr-forum.967333.n3.nabble.com/template/NamlServlet.jtp?mac > ro=unsubscribe_by_code&node=1558041&code=cGFyYWRveEBhczZqZy5mcmVldWsuY > 29tfDE1NTgwNDF8LTE2MTcwNTA2ODE= > > > ----- > No virus found in this message. > Checked by AVG - www.avg.com > Version: 2015.0.6125 / Virus Database: 4419/10633 - Release Date: > 09/13/15 -- Sail when you can, row when you must, motor only when you have to be at work in the morning. Alastair Law Yeovil, England. <http://www.little.jim.freeuk.com> |

|

Paul H (admin) |

Re: How to cut an aluminium mast in 5 seconds

|

|

In reply to this post by John P

John, Al,

I'm glad you all had a good time and yes it looks like the conditions turned out ok for me. I was unsure about the strong-gusts weather forecast, anchoring and whether I could cope with things, but it looks like you found a perfect mooring spot. regards Paul |

|

|

Paul - I wondered if the tube you are considering is 6063 T6 (which has a proof stress of about 170MPa) or is it 6082 T6 (which has a proof stress of about 250 MPa). I would have thought the later to be superior for your application.

Chris - coming back to your interesting questions - Point 3 (which is out of order!) - Agree that unless you have a reefing arrangement that allows easy 'infinitely variable' sail area (e.g. as Alatair has on the Paradox) it is better to reduce sail in large steps. You dont want to go through the hassle of taking a reef then, as the wind continues to increase, realise almost immediately that you need another reef. I agree that there are times when a topping lift could be useful, for example when coming up to a jetty and suddenly realising that it would be better to be rowing than sailing! For this situation I have thought of having just a single light cord, say 3mm, fixed at the masthead and terminating with a small hook that would normally be stowed down near the gooseneck. There would also be a light cord about a metre length, one end fixed to the boom about 2/3rds out from the mast and the other end terminating in a small hook, this cord being stowed along the boom when not in use. Then the sail could be lowered and bunched up to the boom, the boom lifted to above rowing head height and the cord attached to the boom looped round the buddle and hooked to the cord attached to the mast head to hold the boom and sail temporarily clear for rowing. Of course it would all be tidied up properly once alongside. This is something I might try next year, there is already a fixing point at the masthead that is currently used only for a flag halyard on ceremonial occasions. I would say that we do seem to have a tendency to get our halyards in a tangle so I am wary of having any more ropes on the mast then really necessary. We do have all external halyards, a choice made due to wanting to keep the mast sealed although realistically I am not sure that this is much of an advantage. I suspect that internal halyards would reduce rope tangles considerably - half the number of loose ropes. Point 5 - You ask how the French trimarans allow the mast to rotate. Well, I took a close look at the mast on the MOD 70 'Prince de Bretagne' while it was briefly alongside in Plymouth. As far as I could tell the shrouds and forestay were attached to the mast at the sides and leading edge as they would be for a non-rotating mast. However, the other end of the shrouds are taken to hydraulic rams installed in the floats, the primary purpose of these being to tilt the mast up to 10 degrees to windward but they would also permit the shrouds to be adjusted as the mast rotates. Point 6 - You ask whether the sail slides are captive on our boat. Yes they are, the arrangement being, if anything, even simpler than a 'gate' on the mast. There is simply a length of cord about 150mm long, one end fixed to one side of the mast and the other having a loop that can drop into a plastic hook fixed to the opposite side of the mast. The plastic sail slides run in the groove in the aluminium mast extrusion, but the arrangement would work equally well with sail slides that run in a track fitted to the back of the mast. Point 7 - The advantage of a sleeve with cuttouts for attaching the halyard would only be an arguably smoother airflow over the yard and sail. A sleeve luff works well on windsurfer rigs and on those dinghies which do not need to raise and lower their mainsails - for example the little red and white boat Mark S. takes to Cobnor. ------------------ Re. the Bermudian/Gunter arrangement: I have never been sure that my gunter rig that can convert to a small bermudian rig is better overall than the obvious alternative of a bermudian rig that can be deeply reefed. There are advantages both ways, as follows: Certainly, in strong winds our boat feels very comfortable with the gunter yard stowed down in the hull and the small bermudian sail hoisted to the head of the short mast. On the other hand, in light winds when we set our gunter mainsail, the overlap of the two spars means that the weight of spars is more than for a similar size bermudian rig but in light winds the extra weight up high is of less importance. You could think of it as a short masted bermudian rig optimised for strong winds but with an extension that can be added to the mast for light winds. The biggest disadvantage of our arrangement is that changing down from the reefed gunter mainsail to the small bermudian sail, or the reverse, are awkward operations, particularly when the change needs to be made at sea in worsening conditions. I have never timed how long it takes to change to the smaller sail at sea but I would guess that it is about ten minutes during which time the boat is probably uncomfortably rolling about and making no windward progress. We do try to decide before setting sail whether it is going to be a 'big sail day' or a 'small sail day' then set off with the appropriate rig. Leaving aside performance under sail, the short spars of a gunter rig have practical advantages that may not be fully apreciated by those who have only sailed with bermudian rig. The mast is the same length as the hull and the yard a bit shorter. The mast is light enough to be just lifted up and plonked into postion when rigging the boat. The mast stows neatly above the hull when trailing and when the boat is stored on shore the mast remains in that position acting as a 'ridge pole' for the plastic tarpaulin that we use as a boat cover. If we need to park the car and boat in a car park which has only normal length car spaces available we can do so since once the boat is detached from the car it will fit in a normal length car space. For inland waters where sailing is mostly not practical we can row the boat with the mast down and one end of the mast under the fordeck. |

|

Chris Waite |

Re: How to cut an aluminium mast in 5 seconds

|

|

Ahh, Johnny P!

Number 3 was out of order because you started off answering it in the initial paragraph, before reverting to the numbered ones and subsequently completing the answer in numerical order. Now if you'll just excuse me I'm going to escort my OCD off into a corner And go with it to make sure nobody disturbs it Get out of that, without tacking? Christo-picky-well Waite |

|

Paul H (admin) |

Re: How to cut an aluminium mast in 5 seconds

|

|

In reply to this post by John P

John, I just rang Metals 4U and the type of ally depends upon shape and size. They consider both 6063 and 6082 to be medium strength, without much difference after cutting and welding. But the 2 1/4in x 1.6mm tube I was considering is 6082 so that's good news. cheers Paul |

|

|

Cutting has no effect on the strength of 6082-T6 or 6063-T6.

Welding takes both back to T0 temper in the heat affected zone, which is far weaker than T6. You can get both alloys back to T6 by post-weld heat treatment and ageing, but it's beyond the capability of most amateurs. In general terms 6063-T6 is a non-structural "decorative" alloy, used frequently for things like trims and anodised decorative stuff, whereas 6082-T6 is a structural alloy, frequently used in things like light aircraft construction (it's pretty much exactly similar to the US alloy 6061-T6 which thousands of light aircraft are made from). If strength is needed, then 6082-T6 is a more efficient material to use than 6063-T6, as you need less of it to achieve a given strength. It's pretty much the same tensile strength as mild steel, but significantly more flexible due to the lower Young's Modulus (which is the same for both of these alloys). AFAIK, the alloy of choice for masts and spars is 6082-T6, or perhaps 6061-T6 if they've come from the US, as it is pretty corrosion resistant, far stronger than the decorative alloys like 6063 and easy to machine. It also takes anodising reasonably well. Personally I never, ever, use 6063-T6, not only because it's much weaker than 6082-T6, but also because it doesn't machine as nicely. |

|

Chris Waite |

Re: How to cut an aluminium mast in 5 seconds

|

|

In reply to this post by Paul H (admin)

I have been through this topic again and again and I still cannot see where you mentioned the original requirement for some aluminium tube Paulie. So I am not sure what you're intending to do with it; a new purpose made mast I assume....

Am I losing my marbles? (Be kind) CW |

|

Paul H (admin) |

Re: How to cut an aluminium mast in 5 seconds

|

|

Chris,

Likewise I'm not sure where I first mentioned it, but I found an online metal supplier that could do 4 metres of 2 1/4in alloy tube for £27, about half the price of Douglas Fir from Robbins Timber: http://www.metals4u.co.uk/aluminium/tube/57.1mm-x-1.6mm-(-2-14-x-16swg-)/p13120 Ideal for a new main mast perhaps, perfectly round for Gunter and Gaff. -Paul |

«

Return to General Discussion

|

1 view|%1 views

| Free forum by Nabble | Edit this page |