On a shoestring in a shoebox.

1234

1234

|

Chris Waite |

Re: On a Shoestring in a Shoebox.

|

|

Just in case it is a help Ray

I made the join for the two halves of my skiff by setting up bulkheads the same as yours, but with a third half inch (12mm) piece in between. Before proceeding to epoxy, I sliced this round at forty-five degrees to form two interlocking banana shapes:   This locates the two halves very precisely and discourages any splashing. It worked extremely well until I hit a rather abrupt wash, when the two eight foot halves came to a directional disagreement which tore the lips of the flange effect slightly:   Your shorty might well get away with it altogether, but I had to install a substantial stainless double clip, through bolted:   She has been good as gold since. Again, I did not want to bother with bolts and wing nuts to accidentally fall in the grass on the bank, or worse into the water, so she is held together under the inwales with offset cleats that not only oppose the two halves, but pull the flange joint tighter as they are lashed down. This is supported by two stub-wings that not only hold the rowlocks in either aft or forward positions, allowing the oarsman to move forward when there is a passenger on board, but they also lock down over the gunwales with cleats locating in rectangular holes, again lashed together, clamping across the joint:   The only disadvantage with the skiff is that the arrangement had to be sufficiently substantial to cope with the strains half way along a narrow, sixteen-foot boat and thereby hangs a weight penalty. Care to join in? Chris |

|

|

This build seems to be having some issues with cracks at bulkheads

http://messing-about.com/forums/topic/8982-repair-advice-sn-10-nesting-bulkhead/ |

|

Nesting Ray. |

Re: On a Shoestring in a Shoebox.

|

|

Hello Chris.

That's a very original method of yours. I think maybe as you say the length of boat was a major factor in cracking. I might just have borrowed the idea from you if l hadn't already opted for the bracket method which l decided on earlier. As l have already made the cutouts in the bulkhead l am now committed. I will post some pictures of of it when l get round to fitting. Much easier than trying to explain in words. |

|

Nesting Ray. |

Re: On a Shoestring in a Shoebox.

|

|

|

|

Nesting Ray. |

Re: On a Shoestring in a Shoebox.

|

|

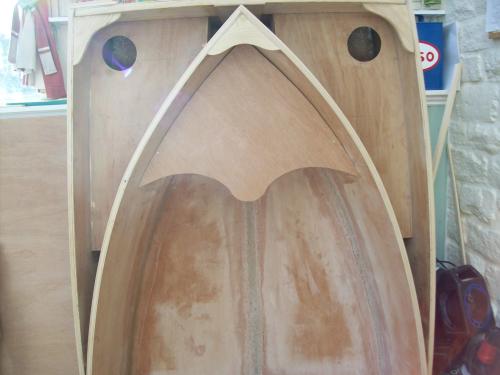

Here we go again, me showing my ineptitude at posting pictures with a touch screen tablet. I think it will be easier for me post in 2 parts ie. Photos then text. Photo 1 shows making the top for the fore buoyancy chamber. 2"x1" scribed to the sides, and mast partner made from 4 laminations of 6mm ply. Photo 2 was not intended to be posted but it appeared, but it shows both parts nested. Photo 3. I removed the top structure in order to use it as a template to mark the ply to save having to try marking in situ. ith. Much easier. I also used the pan lid for more even curves on the back edge. 4 shows the ply top fitted, l have not drilled out for the mast as l am not sure what diameter this will be yet.

|

|

Port-Na-Storm |

Re: On a Shoestring in a Shoebox.

|

|

Well done Ray,

Use of random circular objects to draw curves is one of the more advanced techniques used by the home boat builder. "Nesting Ray. [via UK HBBR Forum]" <[hidden email]> wrote: Here we go again, me showing my ineptitude at posting pictures with a touch screen tablet. I think it will be easier for me post in 2 parts ie. Photos then text. Photo 1 shows making the top for the fore buoyancy chamber. 2"x1" scribed to the sides, and mast partner made from 4 laminations of 6mm ply. Photo 2 was not intended to be posted but it appeared, but it shows both parts nested. Photo 3. I removed the top structure in order to use it as a template to mark the ply to save having to try marking in situ. ith. Much easier. I also used the pan lid for more even curves on the back edge. 4 shows the ply top fitted, l have not drilled out for the mast as l am not sure what diameter this will be yet. If you reply to this email, your message will be added to the discussion below:

http://uk-hbbr-forum.967333.n3.nabble.com/On-a-shoestring-in-a-shoebox-tp4027242p4027352.html

To start a new topic under Builds in Progress, email [hidden email]

To unsubscribe from UK HBBR Forum, click here. NAML |

|

Nesting Ray. |

Re: On a Shoestring in a Shoebox.

|

|

Hello each. Just a quick update of progress so far, albeit rather slower progress than my initial burst of enthusiasm. I have now made and fixed the dagger board trunk also the central removable thwart. I have used 2 stainless 8mm eyebolts to join the the 2 sections, these will be used for mooring lines. All joinery is now complete, so it's on with the sticky stuff now. I will be taping all external seams and the then Sheathing with the poly cotton sheets as recommended by Mr. Waite. I shall attempt to get it to the rowing stage in order yo bring it to Beale in June. The rag and stick will be next winters little project. All for now, cheers all. |

|

Paul H (admin) |

Re: On a Shoestring in a Shoebox.

|

|

No no no! Don't tape the seams if you sheathing.

Taping will spoil the looks and sheathing will give strong seams and protect all the hull. Paul |

|

Nesting Ray. |

Re: On a Shoestring in a Shoebox.

|

|

Wow Paul just in time,l was just about to start. I was going to feather edge the tapes when dry, then sheath with poly sheets. Are the sheet strong enough on their own? I have filletted and taped the insides. It would save me a lot of work if l do as you say. Cheers. Ray

|

|

|

I would suspect that the fillets and taping on the inside is MORE than enough for strength in the joints. The reason I believe the outside is usually taped, is to protect the corners from abrasion, and then the subsequent ingress of the wet stuff which will rot the wood and weaken the joint that way. Do you have confidence the sheeting will achieve this aim? I'd have thought so.

Just my ha'porth. Ian |

|

Paul H (admin) |

Re: On a Shoestring in a Shoebox.

|

|

In reply to this post by Nesting Ray.

Ray,

Many of us sheath the outside as we dislike the taped finish, which can spoil the look of one's quality woodwork. Smooth the external seams with a power sander, prime with thin epoxy then fill the gaps with thick epoxy ensuring that all the end grain is sealed. Sand smooth the next day. Each person has their own technique, but I have found it is important to saturate the wood 10 mins before adding the cloth. After it soaks into the grain add some more epoxy. The cloth can wick away a large amount of epoxy, which can weaken the bond if you don't use enough epoxy. I also like the wallpaper approach - wet out the cloth, roll up then unroll over the hull. Then add even more epoxy and smooth with a squeegee. The cloth colour will "disappear" when saturated. paul |

|

Port-Na-Storm |

Re: On a Shoestring in a Shoebox.

|

|

Don't forget to Iron the polycotton first or you'll get an interesting crushed velvet effect, which some might think attractive.

|

|

Chris Waite |

Re: On a Shoestring in a Shoebox.

|

|

In reply to this post by Paul H (admin)

Erm!?

Gathering up my belt and braces, I fillet and tape inside; then tape outside, feather the edges and sheath over the top. I don't think the minimal visual disturbance caused by a slight edge has made people stop, gawp and point, but maybe they only do it behind my back. Keeping the edge of any tape straight is the most important cosmetic necessity, otherwise it looks worse than old knicker elastic. Belt, braces, bicycle clips, puttees, spats, spare sail-tie, chastity belt, penis sheath, externalized Y-fronts.... Paulie, I'm interested to know what you shuth, or should I say sheathed? And how and in what you manage to evenly epoxy-soak most of an eight by eight foot sheet without the whole thing turning into a smouldering scale model of the Himalayas with real time rock formation? I have stuff to learn, obviously CeeDubbaya |

|

Nesting Ray. |

Re: On a Shoestring in a Shoebox.

|

|

Hello all again. Here's a quick post about my slow progress, boat is all polycottoned and sanded ready for painting. The photos show the bottom joining brackets, this is a trial method and l am not sure how they will stand up the job. I shall only be using the boat in placid waters, not in the sea so there shouldn't be too much stress on the joint. If all goes well l will have some stainless ones fabricated. This method should allow both the parting and the rejoining of the fore and aft sections whilst on land or with practice in the water. We will be coming to Beale Park but will unfortunately not be bringing the boat, we will be towing our caravan and after the the show will be staying out for the week, and the boat will only get in the way. I look forward to meeting everyone and putting faces to names and hopefully having a beer or three with you all. |

|

Chris Waite |

Re: On a Shoestring in a Shoebox.

|

|

Doesn't the boat take apart to go inside the caravan Ray?

Your latches should work fine; they're a lot like the ones I eventually worked out for 'Octavia':  ....here are the halves of the boat, one laid on top of the other, to show both clips; stainless-steel pointy plates through bolted with penny washers the other side. ....here are the halves of the boat, one laid on top of the other, to show both clips; stainless-steel pointy plates through bolted with penny washers the other side.

I hope you found some smaller quantities of two pot polyurethane paint - I seem to remember all three companies (SML-Jotun / International / Epiphanes) do it in single litres if not 750 ml. Beale, then Chris W |

|

Nesting Ray. |

Re: On a Shoestring in a Shoebox.

|

|

Thanks for the encouragement Chris, l really would love to bring the boat, we shall see. I have tried a couple of places for the paint, but they only do the 5ltr tins, this we also shall see. I am looking forward to Beale l have been before but this time l will have more interest because l now actually have a boat instead of a dream.

Ray. |

|

Chris Waite |

Re: On a Shoestring in a Shoebox.

|

|

Have you tried ordering on line

Or phoning up the companies, particularly SML/Jotun? CW |

|

Nesting Ray. |

Re: On a Shoestring in a Shoebox.

|

|

Hello Chris.

Just phoned, SML the nice man on the other end informed me Jotun no longer decant less than 5ltr amounts. He was quite apologetic and fully sympathised with our predicament, that being the fact of only needing 20% of what you have to pay for. I will have a look around the stalls at Beale there may be some old stock around. Failing that the boat my have to go swimming in its poly cotton pyjamas. Cheers Ray. |

|

Chris Waite |

Re: On a Shoestring in a Shoebox.

|

|

Here you go Ray

Not Jotun, but two others I have used to good effect: http://www.tridentuk.com/gb/product-international-two-part-polyurethane-perfection-gloss-750-ml-ip-yh.html Or: http://www.epifanes.com/home.htm Both of these are in 750 ml packs. I don't know how near you are to a chandlers, but they normally hold some stock from these companies. I note that International are so keen to sell their stuff, they don't appear to bother with telling you what they do, but leave it to the distributors of which Trident UK appears to be one - there are loads of others if you just ask Google for 'International two pack paint'. I despair of the reticence of the producers - they and the distributors between them make it almost impossible unless you already know exactly what you want and are prepared to go to hell and back to persuade the internet to fess-up. Come the revolution, programmers and web-page designers will be first against the wall, I tell you Shakespeare said that "Genius is to madness near aligned" For my part I'd say "Arrogance is to ignorance...." Chris W |

|

simplesimon |

Re: On a Shoestring in a Shoebox.

|

|

Try Marine Industrial in Worsted (as in wool cloth)

www.marineindustrial.co.uk Simon |

«

Return to Builds in Progress

|

1 view|%1 views

| Free forum by Nabble | Edit this page |