Creating Curvy Mabel

|

|

This post was updated on .

It was on the first of April that I went into the garage, took from my cache, then wrecked three perfectly good sheets of what used to be 'WBP' (Water & Boil Proof, i.e. exterior grade) 4mm ply. Heaven knows what complicated alternative label it now has. I use exterior grade as my meagre boatbuilding forays do not warrant anything as grandiose as marine ply and there is this waterproof stuff called 'Epoxy', which as my chum Graham points out, has been able to fill any hole he has so far created. Actually he's quite the expert Wood-weaver; some of my holes are much, much bigger, but the theory seems to have held so far.

Have a quick check on this HBBR link and you'll have a better idea of what I am up to - http://uk-hbbr-forum.61.s1.nabble.com/template/NamlServlet.jtp?macro=search_page&node=1558041&query=Perfect+River+Raid+Boat I've been fondling the cardboard cut-out of my next rowing skiff with increasing frequency as we get back up to epoxy-curing temperatures and along with the daffodils, I began bursting out all over. For well over a decade now I've had this idea, this 'Premise' that there's nothing wrong with flat bottom boats that have just a bilge seam each side and the chines turned-up forward to discourage slamming to windward. Happily they also sit stable-lily on the foreshore for camping purposes. I've produced, in my head at least, half a dozen or more hulls that follow a set of simple parameters, so you can squeeze the length, beam and depth to any size that suits you. Bring on the transmogrification! One of my other 'mores' is to try and maximise the use of the plywood, so that the first Premise is a little lugger, a sheet and a half, twelve foot round the sides and half a sheet high amidships - two foot at her deepest point. But why tell you this when it's all been said before? 'Evolving Polly Wee' is quite the saga and it's right here on this forum - http://uk-hbbr-forum.61.s1.nabble.com/Evolving-Polly-Wee-td3339755.html In fact it rambles on forever and explains in gory detail the trials and tribulations from Sheet to Shore and Sea - Ply to Pebbles and the Great Beyond, or what you will. There is so much detail that a repetition here is utterly superfluous. Thus, I expect this to be more on the philosophy and a whole load shorter, but don't actually hold your breath. Whatever There has been chat over the years of a river-raiding craft and this is my version -  Curvy Mabel is the title character in a short, but ribald verse (very non-woke) and I had to adjusted it to suit the occasion; here are both versions - He drank with Curvy Mabel The pace was fast and furious He slipped beneath the table Not drunk, but merely curious (Maybe he was interested to check who was wearing the pants?) Aboard the Curvy Mabel The Raid* was fast and furious It seemed that she was able Though her shape was rather curious * 'Raiding' is a somewhat recent phenomenon, seemingly invented by the French ('Rade'), consisting of 'Competitive Cruising under Sail and Oar'. To comply with my specifications above, the skiff Curvy Mabel is sixteen feet - two ply sheets round the sides and sixteen inches deep. Why sixteen inches? Well it's a third of a ply sheet across, so you get three pieces per sheet, or more specifically out of three sheets, two pieces at thirty-two inches wide. They go end to end to make up the bottom, leaving two sixteen inch wide pieces (end to end) over - for one 'side', then cutting the third sheet into three giving two pieces for the other side.... and a third bit for mistakes, or something else if you're lucky. With me so far? Measuring up the cardboard model it only seemed to come out at fifteen feet. Why, Christopher? I scratched my head for a number of days and finally remembered.... The garage in our last place was just less than sixteen feet long, so not only would building have been a nightmare, I'd never have been able to store her in there. I built one sixteen footer in there; it was a nightmare. This is Octavia, well featured in the first link above and the reason I have moved on, is that she was rather narrow to live out of and had a major double-bulkhead amidships that would have made sleeping aboard an eye-watering proposition -  Here is a diagram of the midships sections of Octavia inside Curvy Mabel; just that extra bit of space -  More to come Of course CW |

|

|

Ah the unmistakeable lines of a Premise bow.

Neat Work CW, and so fast. It's taken me three times as long to get half as far. Keep us posted. |

|

|

In reply to this post by Chris Waite

What is her beam Chris? 3ft 6in is my estimate.

|

|

|

Well Grum

"Neat Work CW, and so fast" is a large part of the point; a Premise shell has only four basic seams - 1. A stem-forefoot combo. 2. A chine to port 3. Another identical chine to starboard, (otherwise it would go round in circles) 4. Around the transom Considering this unseamliness and the restrictions of simple curves, I have tried to imbue her with as much, er, 'sinuosity' as possible. Beauty however is in the eye of the beholder, so only you, dear reader, can be the judge of that. You're not far off at all Paulie, the beam is 45" - 3.75 feet. The shape of the stem is intended to provide the best compromise between waterline length and grounding, on the foreshore, or a wheeled receptacle; it is also (just about*) tolerated by tortured ply, gives a nod to airflow over the bow and has flavours of Vikings and ripe Hobbit about it. *Now I say 'just about', as the most difficult bit in the whole boat comes right at the start. Trying to get the chines to rise up the stem, half way up actually; just for the aesthetics, my favourite. Trying for that is a nightmare that I have not yet perfected; the rest of the boat is too easy. This is my third attempt, no - sorry, fourth. The first was the original lugger and between the bow and the chines and crisp, emaciated ply (4mm, that I was going to bolster with layers of glassfibre sheathing), I actually made a hull and it looked so awful I destroyed it and started again -  But you gotta soften those chines, a truly 'flat bottom' dinghy can 'slam' appallingly to windward in anything of a lop. OK, I suspect someone is going to point to the Paradox, but that's why it has the name; it is the exception that proves the rule. I suspect this is largely because it has very little rocker, a load of ballast and is sufficiently narrow**. So far these are the parameters, or steps if you will - 1. Choose a maximum beam for your flat bottom; remembering that ply sheets are only **four feet wide. Matt Layden, the 14' Paradox designer, was obviously aware of this. The hull gives me the impression of a sharpened pencil box, cleverly fitted with the superstructure of a Ford Anglia. However the proportions are just right and it is an extremely ingenious design -  2. Unless you are a true miser, cut your rectangular width out of a ply sheet and take it to the building frame you have already fabricated -

When I started, the fore-and-aft flatness of the bottom, (lack of 'rocker' - banana shape) seemed important, though I can't quite remember why now, but it has become a habit. To this end, it was necessary to hold the ply very firmly. I was in communication with a Frenchman at the time and the structure reminded him of a Tripalium - a Roman invention lashing three spears together and then some poor unfortunate to that, prior to an afternoon's entertainment drinking wine and ensuring his unpleasant demise. We are a nasty, nasty species, aren't we? The first piece of hull was similarly unamused.... Now the ply-wrangling begins; taking a dustbin lid and marking the curve of the forefoot each side of a midline, cut away the spare - Of course it doesn't have to be a dustbin lid, but it was the nearest round thing to hand that brought the horizontal keel-ward seam up to vertical at half way up he stem which is going to be one and a half times the maximum height of the side strakes, which are cocked-up forward to achieve the striking(??) stem effect. I'll come back to this. How far back does the forefoot seam extend? Dunno really, but I'm probably slowly extending it, as I'm sick of having to disguise small ruptures in cheap ply at this, the most tortured area of the whole boat. The other thing I've done on this fourth hull, is to spread the (wealth?), no - 'stress', by cutting out reducing triangles of spare ply and inserting them under the forward point of of the frame, which encourages the bottom board to bend more gradually -  See the V frame holding the board down to a now obscured central beam, which is the keel support of a T underneath and the triangles, (sorry, they're a tad faint)? Now this shows the process of starting to pull the forefoot together as well But that comes in the next chapter.... Chris W |

|

|

I totally agree about the hull slamming in lumpy stuff, MilliBee is fairly flat to create cabin space.

Motoring out of Cowes at high tide with confused sea she slammed badly, I just hung on tight to the cabin sides until we escaped the harbour. Ironically I was towing Al in his Paradox into a Northerly straght down the Medina. But don't forget the Lynx14 and Paradox heel in a good blow. Then the chine digs in and slices through the water. It feels like MilliBee planes on the chine panel, speed increases and she points higher. She might not literally plane, but certainly sails well and comfortably if heeled. P |

|

|

In reply to this post by Chris Waite

The Paradox actually has lots of rocker. Under power it slams horribly in the wrong conditions. Under sail it heels and becomes a V bottomed boat and slams not at all. |

|

|

Time passes; doesn't it just? My dotage is proving elusive....

This project has now reached the stage where there is a hull and my emotions are telling me I've nearly finished; I've been at this game long enough to know it's a lie of course. Worse, I'm not sure I like it; it's lurking in the garage, looking large and unfortunate. I hauled it out and tried to stand back, but despite the measurements comparing well with the model, which I think is cute, somehow it doesn't flow the same full-size, leaving me with feelings of a sharpened pontoon, the ensuing doubts are manoeuvering my enthusiasm toward a gaping hole in the aesthetics -  I've done it once before and I'm pretty close to pulling the plug on this one. Apart from anything else I'm not sure how many curves can mysteriously vanish before it should no longer be called Curvy Mabel. I suppose it's not too late to rename it Lilly Kazilly after a restaurant on the Detroit River, but I wouldn't bet it'd do much for the shape. There's likely to be another long gap; don't be surprised if she sails off to the great woodpile in the sky and you never hear of her again Well just bother Chris W |

|

|

She looks very streamlined at the waterline and below.

I think slightly more curve from bow to midships will improve the sheer line greatly. A long length of 12mm x 12mm batten screwed at bow and clamped around midships will give an idea of more curve. Use the bulge factor algorithm for arcs. The bulge is the depth of curve away from a straight line at the middle. Try 20mm, 30mm, 40mm etc. When it looks right, you can repeat the bulge easily the other side. What do other members think? There's plenty of you out there. Paul |

|

|

Woodman Spare That Tree!

It's very difficult for us mere mortals to see what you see CW. We can't see what you have inside your head, or how that might differ from what you are actually seeing with your own eyes. To be honest we can't even see what you are seeing with your own eyes with just the one oblique photograph. Readers I've seen this craft with mine own eyes but that was from within the tight confines of his shed and all I can say is it looked fine to me. Paul may be right; A wee bit flat around the foredeck? Could that be softened with a bit more flair at the gunwale? It's hard to say, and camera lenses do distort things. However it has brought back a memory from long long ago of having a similar dilemma.  I don't think I did it in the end. But I am this time around.  Sometimes we are too close to a thing to really see it. Put it away, give it a couple or six days and have another look. Courage Mon Brave. |

|

|

It's so big and the garage and garden so small

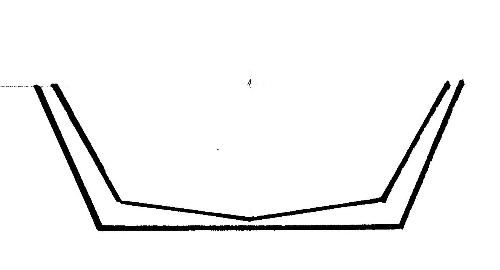

I do agree, it can be difficult to see the wood for the trees, or in this case 'the curves for the conundrums'. The 'swoop for the shear?' Firstly, it's a matter of trying to create a fair curve. You'd have thought a wooden (for instance) batten just the ticket, but trying to find something sixteen feet long, thin and evenly flexible, with a decent drawing edge along it, is somewhere between hen's teeth and impossible.... knot in my back-yard anyway. Unless you know better? What is that pale band just beneath Katie Beardie's original gunwale, Grum? Secondly, my garage is so full of junk, that trying to add ply to itself end-to-end is a nightmare that I have previously compared to taking a Christmas tree into your Arctic bivouac and emerging later having turned it into a sledge. I admit I have only myself to blame. Anyway, there are at least a couple of ways not to do it. Again, unlike two aircraft carriers I could mention, building it in chunks then adding them together is not a brilliant idea. Then trying to shorten sixteen feet of subtle curve, by reducing the horizontal axis some twelvefold and leaving the vertical axis ISQ on an A4 sheet, then transferring the result back to your butted ply sheets, similarly does not work well. The design is utterly simple, in fact the whole sixteen foot shell only has thirty-nine feet of seam-work; no keel joint, just one mirror-image chine each side -  But this time the result is rather squared off midships, looking as if someone, (I wonder who, Christopher), had a packing case in mind. Anyway, to the shear; I know exactly what you two are on about. It is very deliberately lacking forward and this is why - 1. "Cod's head and fishes tail, makes a boat that is sure to sail." A saying of the boatbuilders and fishermen of yore. I don't necessarily disagree with this, but tell me what in nature moves fast floating on the interface between water and air? It's waterfowl trying to take off of course. And what shape are they at and under that interface? Look at a duck or swan for instance; quite fine forward spreading out, to where their little leggies are going like hell and then shallowing up quite abruptly. I can do that 2. I'm an aesthetics nut; when I look at a boat and my designs particularly of course, (of course), I enjoy the ensuing little endorphin kick. There is a measurement being part of a whole (line or rectangle for instance), called the Golden Ratio that pleases the eye - https://www.britannica.com/science/golden-ratio 3. I like to incorporate 1. and 2. above approximately into the shear line and in fact the whole hull, so that the lowest, but beamiest point is, and it's actually about the reverse of a NACA foil - 0.6 of the LOA. 4. Bear in mind that (for me) LWL should be as close as possible to LOA, for maximum possible hull speed. Vertically ended boats though, are not particularly attractive to look at and there are problems associated with that configuration. (Working from back to front), a vertical transom gives a truncated appearance and does not so readily lift to a following sea; twenty degrees has become one of my pet 'rakes'. Not too much, not too little and incidentally it is about the right angle for the back of a seat too, so everything matches. Very pretty 5. Then forward, a squared off forefoot tends to catch in the back of waves when going downwind, thus encourages broaching; it also catches hard on the hard when coming ashore. Very unpleasant, but rounding it off reduces these problems. It helps to keep this 'rounding' as far forward as possible - waterline length again and even a fraction of a knot is a long way for twenty years. 6. This similarly applies to a forward raked stem, which again reduces waterline length compared with LOA. Two other points here, the same design, being further back along the hull, tends to increase the angle of entry compared to the maximum waterline beam and raking the stem head aft encourages better airflow over the hull. To my eye it also increases the general Viking Hobbitude as well; what fun. Now you may think this is all rather pedantic, but any fractional improvement helps over the decades you're going to keep your boat, isn't that so? 7. So here we are back at the shear; that was your point, yes? The curve of the shear might be compared to one side of a parabola, where it straightens out as it runs forward and the curve is maximized aft of amidships. "The flung spray and the blown spume" do not usually arrive from ahead of the stem, or much past amidships; no it comes over the side forward, so it behoves you to have a generous depth forward with the gunwale as high as reasonably possible. The gunwale on this hull, as both the other completed boats and other Premise designs, is actually a straight edge on the side strake, the increasing curve, as projected, being induced by the slight reverse shear at the bow, rolling out to become a 22 degree flare at the maximum beam (0.6 of the LOA from the stem, remember) and tending to become more vertical again at the stern. Parabolic; lovely -  ....but not quite cobled togther Chris W |

|

|

It looks fine to me Chris, I would have no issues with being seen in that hull traveling down the Thames.

Steve

|

|

|

I have to confess to being just a tad confused.

You list a fairly tight bunch of parameters there CW and if she meets them all, then surely she must look as she is supposed to look Nes Pas? Why so troubled ? Personally I take a rather less scientific approach along the lines of "If it looks about right it can't be far wrong" :) The line below the sheer in that photo is masking tape. If I recall it's marking a pencil line which I put there using my best bendy stick, the one I've used on every build. I was seriously considering dropping the sheer a couple of inches midships to save my knuckles but decided I couldn't stand the retribution of the designer. |

|

|

I'm confused as well.

I don't see what is wrong with any curve. Any lower and you lose freeboard or risk capsize. If there's too much windage slice the top off the bow with a jigsaw. Regardless she'll fly along with a 4-stroke, just 8 knots officer. |

|

|

This post was updated on .

Thank you, gentlemen three

Confusion; that's the entity that 'Reigns Supreme', isn't it? 1. Your explanation of the tape and the bendy stick is much appreciated Grum. I should have been before, but must away to Bendystick Wood and cut myself a sliver therefrom. It's quite near Burnham Wood, isn't it? Being a way the other side of Jewsons, I might stop there instead. Yes those parameters are all there, but as Eric Morecambe once said - "Not necessarily in the right order". In fact it is the bendy stick thing; some of the curves could have done with beating into better shape; they lose the line in places and who'd want part of a parabola wearing packing case edges, with straights and bumps and dips in it? 2. Not seeing 'what is wrong with any curve' Paulie, (my eco-warrior with your four stroke), is the inability to appreciate the grace in a sweeping shear, as that model coble on the stair has in my last. It allows you to gaily 'slice the top off the bow with a jigsaw'; you're the one who wrote this - http://uk-hbbr-forum.61.s1.nabble.com/Creating-Curvy-Mabel-tp4032668p4032678.html I told you about the loss of freeboard in my previous upload and would you explain to me what this has to do with capsizing? I have to say that struggling on with finishing the seams has improved my outlook and appreciation, encouraging me to continue. Nearly done that bit.... Stir me up a pot of epoxy and Bring on the 2" tape! Chris W |

«

Return to Builds in Progress

|

1 view|%1 views

| Free forum by Nabble | Edit this page |