The "Aerowherry" a lightweight rowing boat (was going to be a canoe........)

12345

12345

|

|

Ratcatcher John wrote "No doubt Graham, Paul or ToC will point me out to you at some stage and you will be able to extract suitable retribution!"

No sooner said..........  Here he is modifying the captains chair on TBA, no doubt Simon at BTAC is still wondering where that chair went. Graham. |

|

|

In reply to this post by BrianP

Jeremy

To quote your original post - " ...have a go at using them to build a SOF canoe with a slightly unusual twist..." A sort of updated venetian gondola? Aren't you likely to have some steering problems? |

|

|

In reply to this post by Ratcatcherjohn

Whilst the lack of precision may not matter too much in a boat, I would have trouble sleeping at night knowing there was a measurable discrepancy between one side and the other, such as a difference in gunwale length between the two sides. Funnily enough, asymmetry doesn't seem to matter too much with aeroplanes either. I once inspected a home built aircraft where the distance from the rudder post to each wing tip differed by around 75mm (about 3" in old money). There was no easy way to fix the problem, yet the aircraft flew fine when the time came to test it, which goes to show that we can sometimes be just too fussy about these things.

One thing that I am learning fast is that the detail design of things like the way components will be assembled is far, far more time consuming than the "big" stuff, like getting the lines right. Currently I have a fairly firm design that's 5m LOA (around 16ft 5ins) and 0.85m beam (about 33 1/2"). I've worked out a way of connecting the frames to the gunwales, by inserting short plastic slugs into the gunwales at each frame station, then drilling 1/2" holes into the underside of the gunwale and inserting each frame into it. The frames will be secured to the gunwales using another plastic plug inserted into the frame tube, with a stainless self tapping screw inserted into this from the top to hold the whole thing together. Jeremy |

|

|

In reply to this post by Michael Rogers

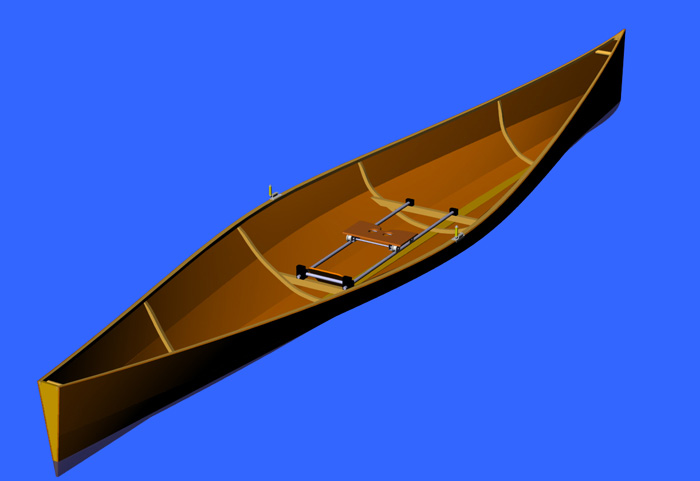

Well, it's sort of morphed from being a canoe to a wherry, and will be rowed rather than paddled, so it'll hopefully bear little resemblance to a gondola (unless I get something horribly wrong during the build).............

Jeremy |

|

|

In reply to this post by BrianP

Thanks again, Brian. I've been thinking long and hard about ways to get a strong and stiff attachment for the outriggers. Something like this kills two birds with one stone, as it resolves the outrigger attachment problem and also removes the shifting longitudinal C of G problem from rowing with a sliding seat.

Jeremy |

|

|

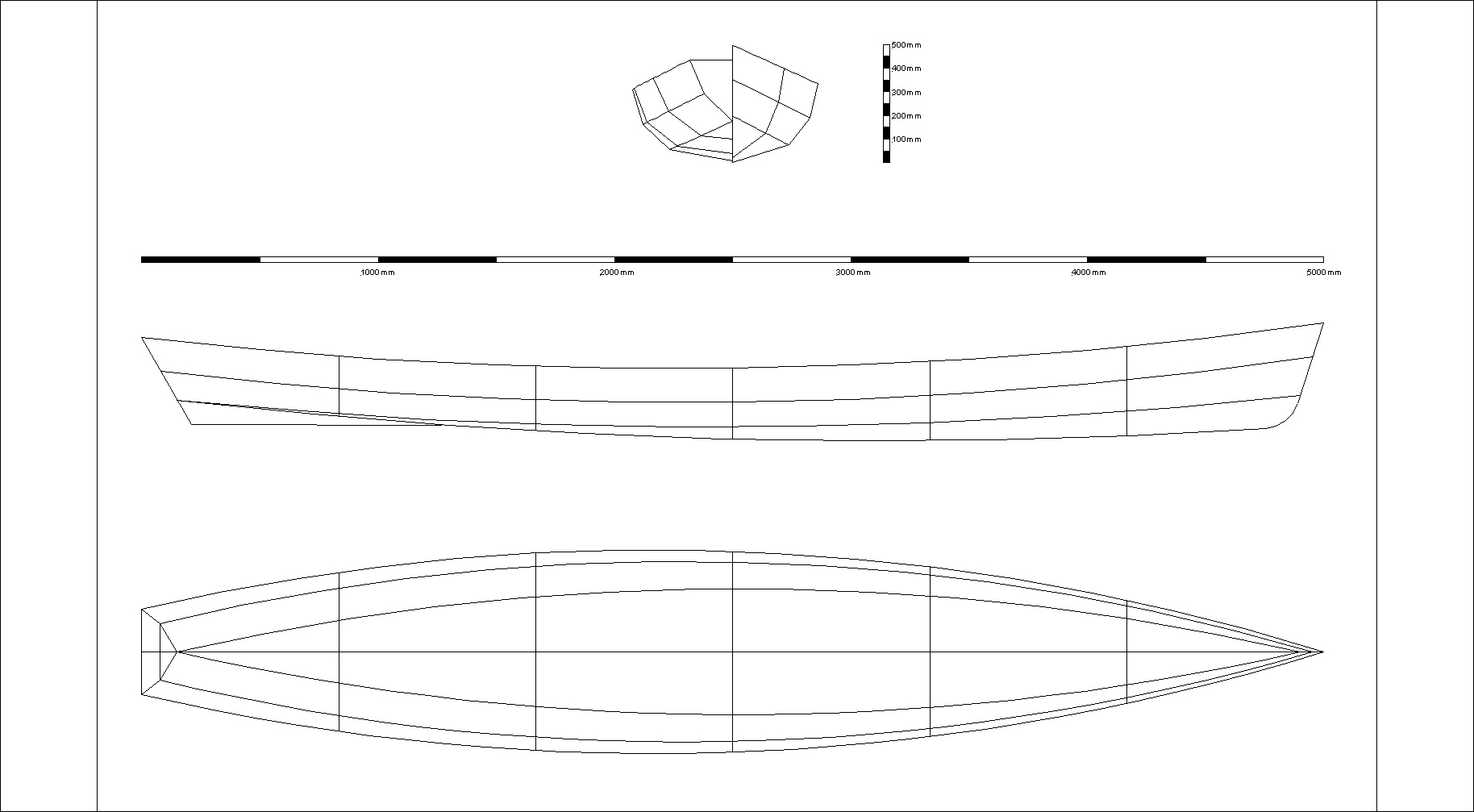

I've finally managed to finish the drawings, except for a few more detail ones showing how parts fit together. Here's a lines drawing to give an idea of how the boat should look:

I'd have preferred a more rounded forefoot, but that would present problems when it came to shaping the alloy for the stem. A straight folded V, with just a hand beaten radius at the very bottom where the keel tube fits should be easier to make, although it does spoil the look just a little. The straighter stem does have the slight advantage of increasing the waterline length very slightly, though. I've run the numbers through Michlet and the total resistance curve looks pretty good. The light displacement helps, but overall it seems to potentially be a fairly fast hull. It could be a little narrower for a slighter reduced wetted area, but I've deliberately opted to keep the beam on the slightly wide side at 850mm (about 33 1/2"), just to gain a little extra stability. The keel section has to be slightly deeper vee'd than would be the norm for this sort of boat, because of the need to keep the fabric tension tight (fabric doesn't work well over large flatt'ish areas without a lot of extra support). There will be a small skeg fitted aft to improve tracking, else I fear she will skitter around a bit, especially with any cross wind. Having decided to not use any wood I shall probably resort to composite over foam core for the skeg and may well use the same technique to make lightweight floorboards and the thwart. As the sun has just come out and the workshop is looking like a more hospitable place to be than it has for the last couple of days, I may go out and make a start on the jigs. I've never designed a boat before, and am really quite enjoying the experience. It has a great deal in common with designing aircraft, although much of the language that naval architects use, together with some of their conventions, seem a little strange. Jeremy |

|

|

Jeremy

Will you have enough of your aluminium tube left over to make riggers (as in a scull)? - because (with a non-scientific eye, but some racing rowing experience way back) I think stability may be a problem. Also, otherwise with only 33" beam, where are your oars going to pivot? 33" beam is, so to speak, neither here (for oarlocks) nor there (without riggers). Would your tubing be strong enough to cope with the leverage created by using riggers? If you've thought of, and already discussed, this elsewhere, please ignore these remarks. |

|

|

It will be rowed now, the design was inspired by a link I gave earlier in this thread to Dave Gentry's "Ruth": http://gentrycustomboats.com/RUTH%20page.html

The plan is to fit outriggers of some kind to get a wide enough platform for rowing, although having seen Brian's photo of a sliding rigger I may have a look at doing that. Strength of the gunwales won't be a problem, as the alloy tube I have is several times stronger than a conventional timber gunwale of the same stiffness; if anything it's massively too strong for the job, but pretty much has to be to get the stiffness up to the same sort of deflection under load as a typical wooden part. I've been pondering ways to fit a seat and outriggers this morning and will have a go at drawing up a simple system with a pair of round rails running fore and aft, like those in Brian's photo of the sliding rigger. I think it might be possible to have these rails do dual duty, as both an adjustable seat mounting point and slider system, provided I can find room for my feet. The hull stability looks reasonably OK from the predictions given by Michlet, it's ultimately a bit stiffer in roll than a typical open canoe of the same LOA, but with slightly less initial stability, so it'll feel a bit tippy at first. It will certainly be a boat that reminds you of the need to step into the centre when boarding! The lines are pretty close to those of a traditional wherry, albeit with a bit less LOA to fit the size of tube that's available (and the cordless challenge rules). I did increase the beam a little and also allowed a little more freeboard amidships, to give it a bit more stability and allowable roll before shipping water over the side, although with a total displacement of around 100kg this is probably unlikely. Jeremy |

|

|

In Finland they have some very fast rowboats and recently changed the rules to allow sliding seats. They are very light and very lovely. The sliding seat design is neat and simple.

http://www.puuvenepiste.fi/  and a video here http://www.youtube.com/watch?v=rUrS37fGnHU Gig Harbour have an interesting post on sliding seats. http://www.ghboats.com/slidingseats.shtm Their own is more a sliding bench, running between square edged buoyancy tanks. Uses vertical rollers to run on and horizontal rollers to hold in place. this system could easily be used for a sliding rigger carriage running between square section alloy tubes.  This is such an interesting thread. There are many manufacturers of alloy tubed boats, it's just they are all kayaks - Feathercraft, Folbot, etc. There seems to be none for rowboats. Ruth has shown SOF works for a rowboat, so this could be a really nice boat. at last a car top fast rowboat that can be loaded and unloaded alone and it width fits a standard roof rack. With sliding rigger as well -- please make the drawing available when she is developed. Brian |

|

|

Thanks very much for those links, Brian, yet more food for thought!

I've sketched up a tube slider system this morning and been out and quickly tested some bits of tube supported at the points that are available on the hull. The stiffness is probably just about OK, particularly as believe that most of the load will place the tubes in compression, provided I can get them high enough in the hull to keep the bending moment down. I think that the Virus rigger tube must be stainless steel, as some quick calcs show that alloy tube of that sort of diameter would flex a lot under even modest rowing loads. As an alternative I'm looking at the way that the Piantedosi system works ( http://www.rowingrigs.com/pubsite/ ).  It may well be simpler to make something that fits to the floors like this, as it could do double duty as floorboards. It'd also be easier to build, as skate wheels could be used (as in the design you posted above) running in channel sections. If the seat/rigger was made quickly and easily removable it would make car topping easy. The plan is to make the design open source, rather as Dave Gentry has done with "Ruth". I'll publish the plans and build details here and if the boat works people can just use this thread to build or modify one for themselves. The only snag with this approach is that I will need to tidy my workshop - it's an unholy mess that won't look good in photos! Jeremy |

|

|

Hi Jeremy, I just logged on to post a picture of the Piantedosi sliding rigger and you beat me to it.

The Virus unit is alloy and you are correct that it might not be reliable. See this post on the Angus Rowboats forum http://angusrowboats.com/support/forum/topic.php?id=22 Thanks for the open source nature of the design. Brian |

|

|

It's a pity that the Virus unit doesn't seem too reliable, but I can't say that I'm surprised, based on the bending load that the rigger tube itself is taking.

I've been experimenting with ways to join the gunwale tubes to the top of each frame this afternoon. The frame to stringer joints are easy, just a long Avdel rivet through each, but I wanted a way of making a neat attachment to the gunwale that will allow the fabric to wrap as far around as possible when it comes time to cover it. After a few abortive experiments with bits of dowel, screws etc, I came up with this:  The underside of the gunwale tube is drilled with a 1/2" hole to accept the frame tube. The upper side of the gunwale tube is drilled with a 5/32" hole to take a long Avdel rivet (the ordinary pop rivet in the photo below is a bit too short, and was just used for a test). I found some plastic Rawlplugs that are a tight fit in the frame tube and on the rivet, so the joint is made by placing the rivet in the hole at the top of the gunwale, pushing the Rawlplug onto the rivet firmly, then fitting the frame tube through the 1/2" hole and onto the Rawlplug. Setting the rivet expands the plug to make a very tight joint indeed, in fact I think it actually expands the frame tube slightly inside the gunwale.  This is a very quick and easy way to fit these parts together, plus it leaves a nice clean finish on the inside. There's no risk of the gunwale pulling off, both because the rivet seems to have expanded to become a very tight fit and also because the fabric will be tensioned very tightly pulling the joint together. The joint has a nice big bearing area on the frame and doesn't require drilling into the load bearing faces of the gunwale tube (the stress will be concentrated on the inner and outer, rather than upper and lower, faces). Much of the detail is now sorted, I just need to try a few ideas for attaching the keel, gunwales and stringers to the transom and then I'm ready to go. All the frame templates are done and I'll publish the table of offsets for the frame jigs shortly. Jeremy |

|

Chris Partridge |

Re: Unusual lightweight canoe

|

|

At the risk of sounding a negative note, I wouldn't bother with sliding seats unless you will be racing. Over the longer distance they aren't faster (because the rower only has so much energy to spend), they add complexity and when you are out rowing you can't shift your seating position at all which is a right rectal ache after a couple of hours.

|

|

|

You may well be right, Chris. I wasn't going for a sliding seat though, the option I was looking at was a sliding rigger. The motivation for looking at them came from the ease with which such a system could be fitted to a strong part of the hull, rather than the gunwale tubes. I think I'll put off the decision as to how to attach riggers until later, anyway, although I may well beef up the centre and immediately aft of centre frames to give reasonably good attachment points.

I'm off out to the workshop to build the frame jig now, should be done by lunchtime and then it'll be on to bending bits of tube. Jeremy |

|

|

In reply to this post by Chris Partridge

Hi Chris, I have to admit to being confused by your fixed seat fixation! It was after all your very self who turned me on to sliding seat rowing in your Sprite. It was just so different, so nice and completely different to rowing my fixed seat tender. It's really nice to use your legs, back and arms in what to me seems to need more skill than I have but is much fun to learn.

As the complete expert around here on all things rowing I feel great trepidation in even trying to write this post. On your blog Rick recently commented" Hello Chris, I have to disagree with you (and John Welsford) again on the sliding seat. Even with our slower recreational boats, a sliding seat lets you use different muscles. It can help a lot on long rows - my back is just not that strong." I have the same logic issues. Forget going fast, just at the same speed in two boats if I am using my legs, back and arms fully then am I spreading the load more across my body so I am less stressed than the boat next door where I can only use my back and arms? I also have a damaged back, so need to use my legs as fully as I can. I know you use your legs in fixed seat but not as much as with sliding rigger. So my logic says a sliding rigger is theoretically better for me and in actual practice far more pleasure. Yet your huge experience says no. Help please! As the only one of us who has rowed the Clovelly Skull any distance ( I tried it and really liked it) isn't the slower motion of the sliding rigger and longer oar sweeter than the faster fixed seat shorter time phase skiff? Please be gentle with masters reply to willing student. Brian |

|

|

In reply to this post by Jeremy

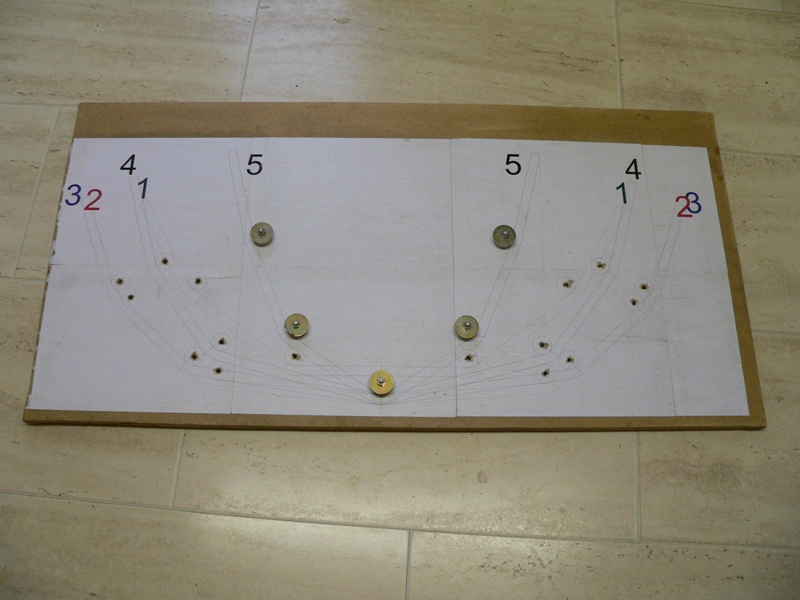

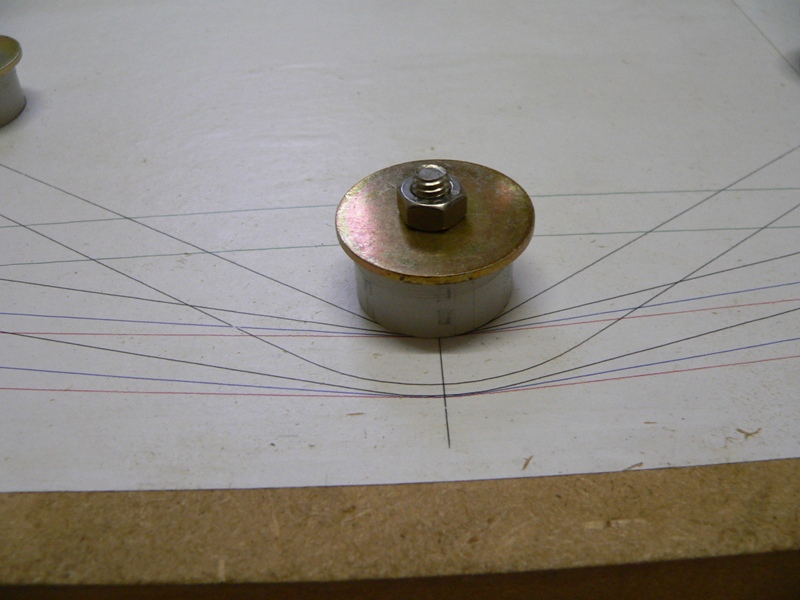

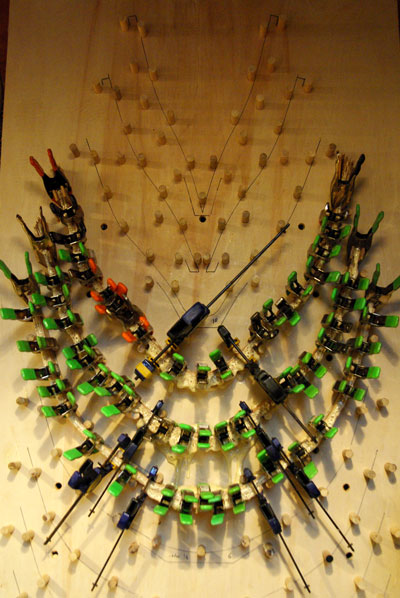

After a fruitful time spent getting the frame lines onto a bit of MDF, via the wizardry of CAD and some careful pasting of bits of printed paper, I've ended up with this frame bending jig:

The one jig can be reconfigured by moving the nylon bobbins to make all of the frames. Here's a close up of one of the nylon bobbins, around which I'll bend the alloy frame tubes:  It took longer than I anticipated because I chose to glue the patterns down and then give them a coat of PVA to seal them, so I have to wait for the PVA to dry before I can start bending the frames. This jig also shows where each frame needs to be drilled for the rivets that will secure the frames to the stringers and the keel, along with the angle of the rivet hole. It should make getting the lines fair easy, provided my CAD drawing is correct. Jeremy |

|

|

That's a stunningly neat piece of work. All ready for a production run! How many do you plan once you've completed the prototype? Tim. |

|

|

Thanks. If it works, then I'll just lend the jig out to anyone whose foolhardy enough to have a go at making another one.

I know it seems a bit of an overkill to make a jig like this just for a single experimental boat, but when I looked at different ways of bending the frame tubes accurately, and marking out the rivet holes for the stringers and keel, it seemed easier, and less likely to result is wasted bits of bent metal, to make a proper jig. Most of the time and effort so far has been in doing all the drawings. Actually making that jig took under an hour, including the time spent turning up the little nylon bobbins. I've also made up a simple tube drilling jig this afternoon, so that drilling the rivet holes in the centre of the tubes will be nice and easy. Jeremy |

|

|

That's very impressive. One of my all time favourite SOF boats is a 13' Adirondack Guideboat by Cape falcon kayaks and their jig for laminating the frames is the same only much more compliacated.

http://www.capefalconkayak.com/adirondackguideboat.html How does the tube bending process work. The bend at the keel of station 5 looks quite a challenge. My dad was a time served plumber and used to bend all the copper pipe over his knee with a spring inside to prevent the pipe collapsing. I think I would like to be included in the queue to use the jig please! Your solutions are so neat. Brian |

|

|

I'm concerned about that bend, too, Brian. I know that this relatively thick wall tube will bend around all the other chines OK without the need for any bending aids, but I think I may need to make up a simple bending tool to get that sharp bend around the bottom of station 5 without overly distorting the tube.

I have some Delrin bar in the "may come in handy" pile, so will machine up a tube bender for that bend, really just a deep pulley the right width for the tube, with an outer roller that can keep the tube snug in the groove. I'm hoping that I'll be able to provide enough documentation via this thread to allow anyone to use these jigs and fixtures to build a similar boat. I had a go at costing some of the materials this afternoon. All of the alloy needed can be bought online for less than £85, including delivery, or can probably be sourced locally for maybe £75. Ordinary 4mm stainless pop rivets can be substituted for the Avdel rivets and will probably cost around £10. The lightweight Dacron cloth comes to about £45, plus another £35 or so for adhesive and finishing tapes. On top of this would be the cost of paint etc, plus rowlocks, oars etc. The basic cost of the hull should come to less than £200 I should think. Jeremy |

«

Return to Builds in Progress

|

1 view|%1 views

| Free forum by Nabble | Edit this page |