MilliBee with a haircut?

1 ...

121314151617

1 ...

121314151617

|

|

Mine helps too, "if you don't get that bl###y boat out of here and clean up l'll do it myself".

|

|

|

In reply to this post by Paul H (admin)

I didn't know the Gloucester Girl Guides were re-building micro-cruisers

I see the skeg is cut away aft. Why did you not run it full depth all the way to the line of the transom? I don't suppose it would make much difference, but anything for a little directional stability.... Or not as the case may be C Grenfell von W |

|

|

Don't know, I just followed Paul Fisher's original design. Rudder clearance? Smoother when hitting a rocky bottom when launching? Less likely to trap lines?  -Paul |

|

|

On 13 Apr 2015 at 5:18, Paul (admin) [via UK HBBR Forum] wrote:

> > > Chris Waite wrote > > Why did you not run it full depth all the way to the line of the > > transom? > > > > C Grenfell von W > > Don't know, I just followed Paul Fisher's original design. Rudder > clearance? Smoother when hitting a rocky bottom when launching? Less > likely to trap lines? > My immediate assumption when I saw it was to allow launching, off the trailer, into shallower water. -- Sail when you can, row when you must, motor when you have to be at work in the morning. Alastair Law Yeovil, England. <http://www.little.jim.freeuk.com> |

|

|

In reply to this post by Paul H (admin)

Remember that wonderful British Rail slogan from the 70s?

We're getting thereBoth bilge slots covered with 9mm ply. Just need epoxy fillets all round to seal the end grain of the ply.  Arty ShotThe centreboard case and skeg will be capped with D section Oak, reclaimed from a large bookcase we bought in America before moving back. The Oak is about 18mm thick, ripped down the middle to give two pieces 18mm wide and carefully drilled (with a Dremel) and pinned with 1.6mm panel pins to the end grain of the case.When cured I'll fill in the 9mm wide gap between the Oak 'overhang' and the hull:  A short section of Oak, suitably notched, will slot in front of the case up to the second bulkhead (under the mast) Beer o'clock ...... cheers Paul |

|

|

This post was updated on .

Joint Executive decision required chaps!

I have a choice between 65mm wide Oak near the bow or 38mm wide both D shaped. 65mm leads into the centreboard nicely with the same width, 38mm is just like the skeg. It's debatable which has less drag. The Lynx 14 design by Paul Fisher specified 65mm wide Iroko for the full length of the hull.   Which one ????????? -Paul |

|

|

I don't really have a vote on this, but my view says go with the wider one. Both artistically because it looks more uniform, and for reasons of strength and durability.

What do the executives think? |

|

|

This post was updated on .

In reply to this post by Paul H (admin)

Wider one looks better to me (but it's not my boat!)

Tim. |

|

|

This post was updated on .

In reply to this post by Paul H (admin)

Well, use the wider one and taper it down at the bow to match the skeg, also taper it vertically so that it doesn't catch on things when you come ashore.

Grum. Nonexecutive director. |

|

|

I agree with Grum

Use the wider one, then get in there and taper it down forward CeeGeeDubbaya |

|

|

Ok chaps....tapering means more hard work.

I don't have a bandsaw (well I had a cheap one from Axminster and its falling apart) but I guess a jig saw will have to do. A gentle curve from 38mm wide to 65mm wide?  -Paul |

|

|

Why bother with a curve?

No one is going to see it, just make it wedge shaped. Rough cut with a saw or jigsaw then plane the edges smooth. Grum. |

|

|

Agreed, rat-catcher agricultural quality is sufficient! I decided the wider piece is more useful in the companionway for a small seat/footstep/centreboard cover. So the single 38mm will be fine...I managed to cut a neat 20 degree leading edge with my chop saw, for fine entry into the water and easy rise onto a V roller. I'll blend it in with epoxy at the start of the case, plus heavy power sanding to keep things smooth. Further forward a brass strip makes more sense - I could nick the one off Tigger! There are multiple overlapping glass fibre sheets near the bow and its very strong. Hopefully we can fit the centreboard tonight.... exciting! ttfn -Paul |

|

|

Drum Roll....I could not resist trying the centreboard. 12mm drill and the stainless pin would not fit, 12.5mm drilll and it wobbled a bit...you can't win! But when the hole is epoxied and drilled a few times the fit will improve.  About 50% area and 36in wide along the hull About 30in deep at this point Fully down, 32in deep by 20in wide View from the insideAll fits nicely at the Bridge Deck  Somebody remind me to seal the pivot before the Thames Raid please.... Paul |

|

|

Nice one Paulie!

CGW |

|

|

In reply to this post by Paul H (admin)

Paul, remember to seal the pivot! Grum. PS well done! |

|

Paul H (admin) |

Re: But does the washboard fit?

|

|

This post was updated on .

In reply to this post by Chris Waite

Oops, I cut the companionway edges vertical to allow more width at the bottom and easier access.

Then later I realised there is no way of having an over lapping hatch edge to seal square boards. Previously I had V shaped washboards - I could slide the hatch right back and fit the top panel up underneath and down into the V. Then slide the hatch forward slightly for a completely rainproof seal with the hatch lip in front of the washboard. So how do I seal rectangular washboards? How did they do it on the Yachting Monthly Senior? thanks -Paul PS: I have all the wood I cut out after fitting and can revert to a V-shape |

|

|

Indeed Oops. or Oh Bugger. Sent from Windows Mail Oops, I cut the companionway edges vertical to allow more width at the bottom and easier access.

Then later I realised there is no way of having an over lapping hatch edge to seal square boards. Previously I had V shaped washboards - I could slide the hatch right back and fit the top panel up underneath and down into the V. Then slide the hatch forward slightly for a completely rainproof seal with the hatch lip in front of the washboard. So how do I seal rectangular washboards? How did they do it on the Yachting Monthly Senior? thanks -Paul PS: I have all the wood I cut out after fitting and can revert to a V-shape

Sail when you can, motor when you can't http://www.millibee.com

If you reply to this email, your message will be added to the discussion below:

http://uk-hbbr-forum.967333.n3.nabble.com/MilliBee-with-a-haircut-tp3727803p4028698.html

To start a new topic under General Discussion, email [hidden email]

To unsubscribe from UK HBBR Forum, click here. NAML |

|

|

In reply to this post by Paul H (admin)

Sorry Paul, think I've got that, but pictures would make it clearer.

Tim.

|

|

Paul H (admin) |

Re: But does the washboard fit?

|

|

This post was updated on .

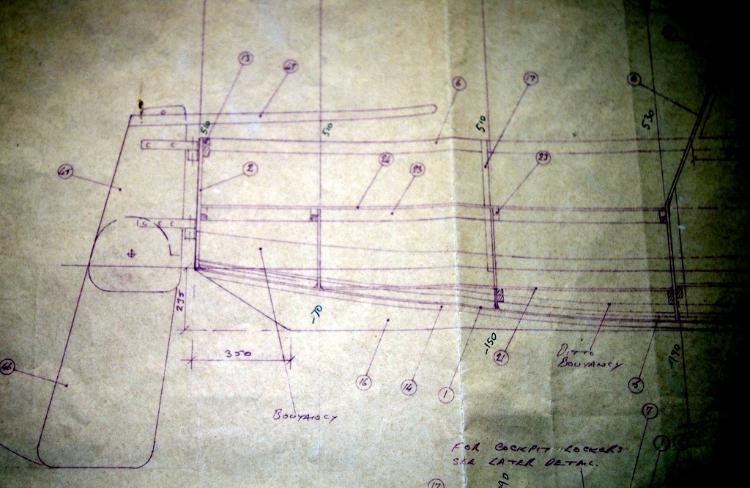

In reply to this post by Port-Na-Storm

Carpe Diem Got up at 7am and already had lots of ideas. My Evolution Rage 3S sliding saw cuts 210mm wide.....so it's very easy and accurate to make washboards 210mm high...or at least prototypes from scrap to figure out the correct angle to cut. Holding the vertical oak rebates at the side of the bottom rebate looks ok...with just a thin sliver of a hole in the bulkhead at the bottom. They used to be on top of the bottom rebate so that's 74mm wider at the bottom already. Timmo, here's a photo of the "skeleton". See how I accidentally cut the opening square.  The washboard can slide up about 40mm behind the front side of the hatch, then pop out of its groove and stowed to leave the companionway clear. It all works because the "V" shape get wider as the boards lift. Likewise at night I lift it high and drop it into the V groove, sliding the hatch atf to seal the gap. It has never let any rain in. So there must be a "V" for this system to work. D'oh  Other systems don't rely on the "V"; the hatch slides aft to touch the inside of the boards, but there is often an overhang on the hatch to keep some of the rain off. The YMS works like this, all the rectangular washboards slide in from the top, then the hatch goes aft. Personally I think the V system is better as the overlap of the hatch should provide better rain/wave protection. The oak is a bit weathered so I will sand the whole lot of paint it, hiding epoxy fixes along the way.  -Paul PS As the roof was dropped 3in all the washboard angles where changed. So new washboards are needed, with a bit of trial and error! |

«

Return to General Discussion

|

1 view|%1 views

| Free forum by Nabble | Edit this page |