MilliBee with a haircut?

1 ...

3456789

... 17

1 ...

3456789

... 17

|

|

Fiddly job, but will look leaner, specially if the roof comes down a touch as well.

Tim.

Looking at all the options to adjust the cabin I realised one of the easy and most beneficial changes is to shorten the cabin, by about one foot: |

|

|

I agree with TimmO and your own observations Paulie

You worry about the detailed profile of the centreboard and the answer is that I am uncertain, but not a lot. I made the boards for my last two little dinghies to just fit inside the case, then rounded off the corners a bit until they started to resemble the profile of a Spitfire wing; oooh, get me! Minor changes like this will have negligible consequences compared to the magnificence of removing the pair of flat-ended bilge boxes that she used to push through the water. Similarly the cabin - you already agree it's too big and if you are going to bring its aft end forward and slope its forward end aft (and are aware that it is too tall), then how about you cut your losses and the cabin off all in one swell-foop and start again? The doctored picture looks pretty well proportioned apart from the height as TimmO observed. I'm going to have to think of a way of improving 'Tit Willow's performance, just to keep up with you CW |

|

|

In reply to this post by Timmo

Tim,

Moving the roof lower is a huge amount of work...basically a rebuild of the roof. But restyling the cabin front is something I have wanted to do for sometime. It looks too long and boxy; when I use a genoa the tack will be low on the bowsprit and its likely to get caught on the cabin corner when tacking or be shadowed from the wind. The Lynx 16 is the look I'm after, notice how Paul Fisher designed a curved front at a low angle which finishes much closer to the mast than MilliBee:  In MilliBee I squeezed in space for someone to sit forward of the arch under the mast (all part of the floating caravan approach!). In hindsight that has made the cabin too long. -Paul |

|

|

In reply to this post by Paul H (admin)

The centreboard slot is now about 4ft 2in long and there is a 4:1 slope at the back as per suggestions.

Next step is the case, dry screwed to check it all fits nicely. The slot will need to be lengthened for the case - some trial and error until it looks about right. Depending on how it feels in the cabin I'll shorten and/or taper the front of the 4ft centreboard slightly....trying to keep the wetted area as big and as strong as possible. The design calls for a 9mm plywood knee across the hull to support the front of the case. I've been wondering how to strengthen the central area of the case which will take the twisting load....probably a ply doubler glued to the case sides. -Paul |

|

|

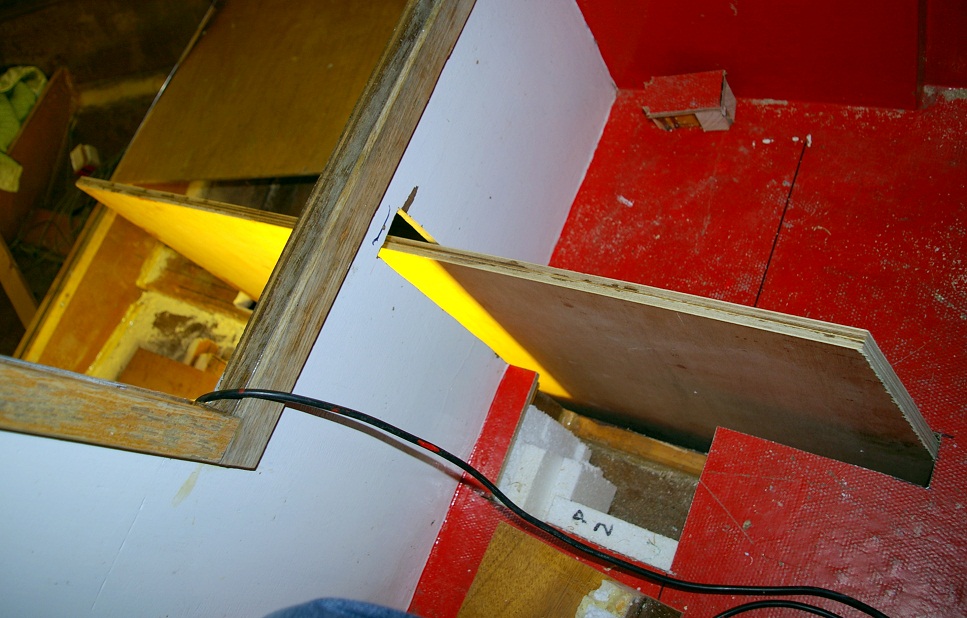

Finally after a lot of fiddly adjustments I have made space for the centre-board case, which is dry-screwed at the moment. This pic shows it in relation to the older bilge boards...the new pivot will be about 10in further back.

The bridge deck is looking tidy but I might lose two inches on the depth:  Underneath I'll trim the case flush with the hull, remove the paint (whats left of it) and glue oak runners to protect the end grain.  Guess who forgot the hardener in one batch of the top coat...  What do you think chaps? -Paul |

|

|

This post was updated on .

It's so cold outside......

... but daughter#2 moved out so I annexed her bedroom within minutes and now have a cosy "hobby" room. I've progressed on the centreboard case, epoxied and almost ready for Jotun 2-pack primer. Here you can see the 18mm board which is 20in wide and 46in long (max), the ruler is one metre long:  It is hinged with a prototype 100mm forward radius to give a wide range of adjustment. The cleat is roughly where it passes through the bulkhead:  When fully down, a corner step into the boat has the dual benefit of taking the twisting load at the rear. A knee across the boat will take the forward twisting load:  So its looking good I think. You can just see a 100mm radius pencilled top right to give a smooth, safe curve in the cabin. I'm keeping the whole thing horizontal to give it a dual role as a drop leaf table. There is a 5 to 1 leverage when the board is fully down, but I think if I build the bottom 200mm really strong the case will be ok. As for the board the bending stress is constant regardless of how much is inside the case, glassed 18mm should be ok. cheers Paul |

|

|

In reply to this post by Paul H (admin)

Some more random doodling...

Original:  Trimmed by lowering and shortening the side panels, then blending away the outer cleat and streamlining the leading edge:  What do the cabin-police think?  -Paul |

|

|

On 25 Feb 2013 at 6:36, adminHBBR [via UK HBBR Forum] wrote:

> Some more random doodling... > > Original: > > <http://uk-hbbr-forum.967333.n3.nabble.com/file/n4026208/untrimmed.png > > Trimmed by lowering and shortening the side panels, then blending away > the outer cleat and streamlining the leading edge: > > <http://uk-hbbr-forum.967333.n3.nabble.com/file/n4026208/trimmed2.png> > > > What do the cabin-police think? > A cabin is there for what is inside it. If the inside still serves it's purpose then the outside is fine. If you can do without the inside then you can remove the outside completely. What I think I am saying is - decide what you want the cabin for, then make it fit that purpose. The lower it is, while still working as a cabin, then the less windage there will be. Tweaking the angles is styling and should not impair the function. Looks ok to me. -- Hoping for calm nights Alastair Law, Yeovil, England. <http://www.little.jim.freeuk.com> |

|

|

In reply to this post by Paul H (admin)

Not highly qualified regarding cabin design but, taking into account Al's comment about keeping adequate inside space, the trimmed version helps Millibee look lighter and sleeker. More graceful. The house behind the bows of Millibee is considerably improved in the second photo as well! Not sure how the residents feel about losing their first floor. On 25 Feb 2013, at 14:36, adminHBBR [via UK HBBR Forum] wrote: Some more random doodling... |

|

|

In reply to this post by Paul H (admin)

On Mon, Feb 25, 2013 at 2:36 PM, adminHBBR [via UK HBBR Forum] <[hidden email]> wrote: Some more random doodling... I think it's too late to think. You appear to have done it already! You may also consider telling your neighbours that they now live in a bungalow.... Pete |

|

|

In reply to this post by Port-Na-Storm

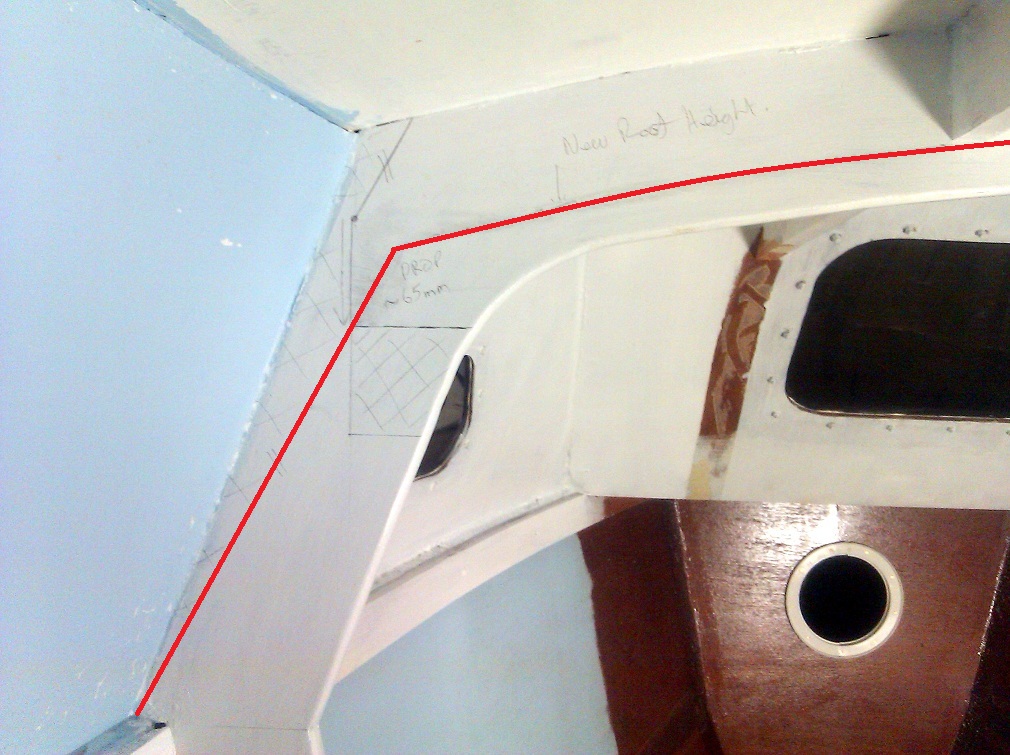

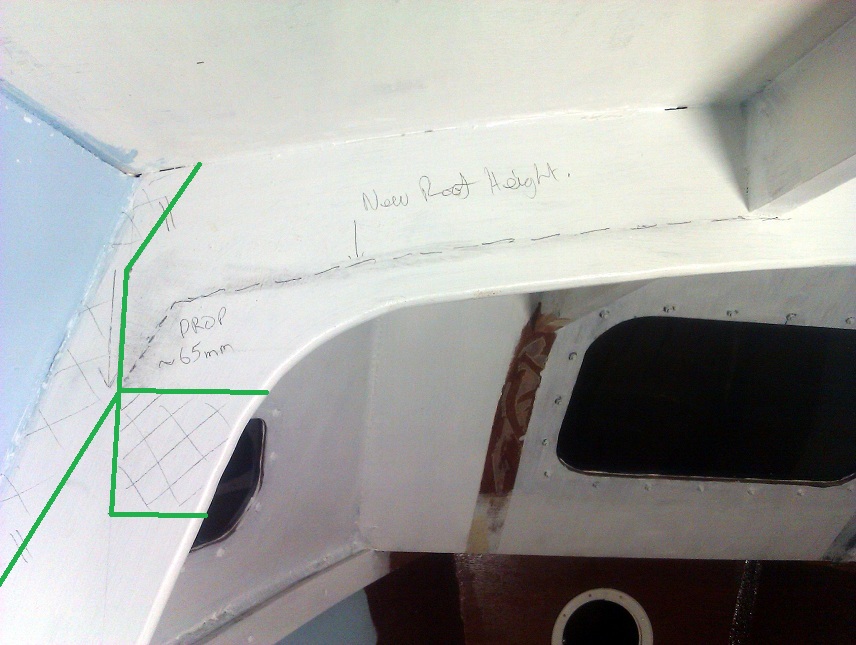

There has been much offline discussion about lowering MilliBee's roof and with the milder weather I have been exploring the options.

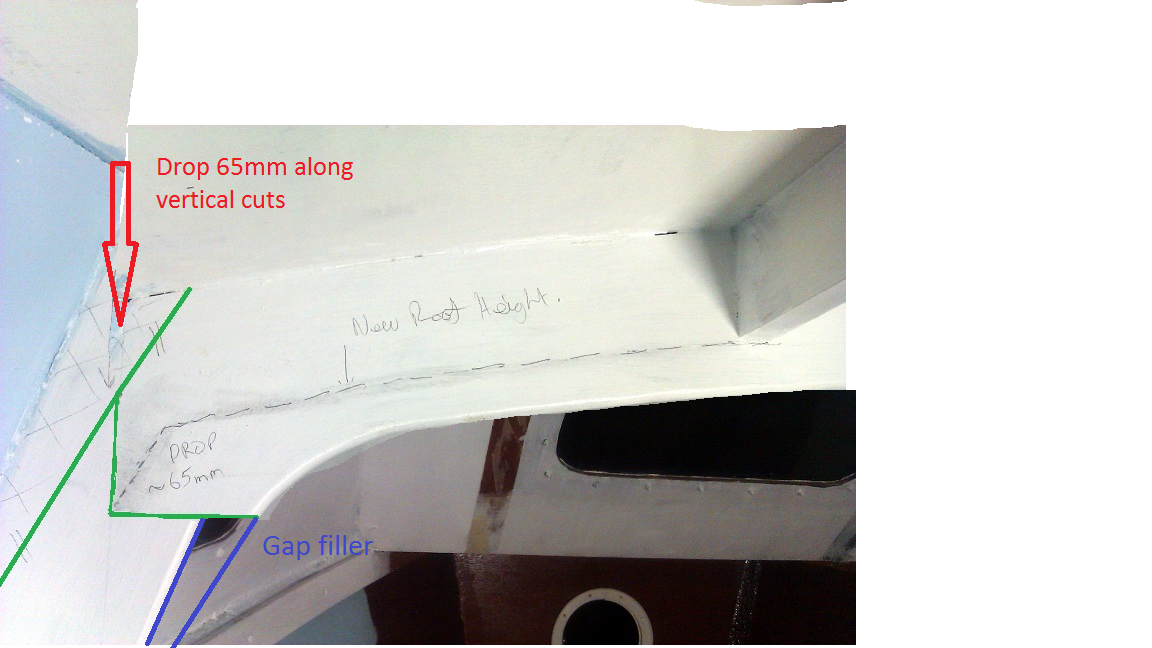

Here are some outline sketches for a roof about 65mm lower, with a shallower side angle. The difficult problem is lowering the arch under the mast and I think have a good solution. The overall plan is a "tin opener job" on the roof (2x4.5mm laminated and very strong) which is reused at a lower height. Hopefully these pics make sense - the new roof profile at the mast arch is shown by red lines and its close to the original Lynx 14 plan:  Below the cross hatched areas will be removed by cutting along the green lines, the lines with 2 pencil marks are parallel. The top section can then drop 65mm to fit onto the L-shaped shoulder:  The new arch can be widened back to 100mm deep with 6mm side plates, filled in with a 18mm triangle section. The main bulkhead is easy to reshape along the red lines:  The front will be moved back up to 9 inches, similar to the original. This will give more foredeck space for permanent stowage of the 5kg anchor and chain. Have I missed anything? Would a video of the "jigsaw massacre" will go viral on YouTube?  cheers Paul PS: Some of the cut lines are not accurate - its a rough plan. |

|

|

Nice one Paul.

Took me a while to see how clever your plan is. Very neat solution to maintaining the integrity of the structure. Look forward to the video!

Tim. On 17 Mar 2013, at 22:06, adminHBBR [via UK HBBR Forum] wrote: There has been much offline discussion about lowering MilliBee's roof and with the milder weather I have been exploring the options. |

|

|

I think that's small, medium and tremendous Paulie!

Just the ticket. Are you going to roll the leading edge of the cabin front up onto the roof, or is that getting a bit technical? And when are you starting and will it be ready for the post-Beale raid, or the Solstice ....perhaps the Winter one? I know it would take me that long CW |

|

|

In reply to this post by Timmo

For months I have been juggling ideas and it seemed the arch had to be rebuilt which sort of implied a roof rebuild....which was never going to happen. But I sat in the boat sketching new angles, then hit the Eureka moment! |

|

|

In reply to this post by Chris Waite

Time is the issue and it will be difficult single handed.......but I think a team of jigsaw jockeys could cut and reshape her in one weekend. -Paul |

|

|

In reply to this post by Timmo

For clarity here is a sketch of the arch dropped 65mm - the vertical cuts make it work:

|

|

|

Will the gap filler will be needed? Could just fair the curve of the roof beam into the existing line of the upright. Can't see how that would weaken the structure enough to worry, even with the mast on top of it.

I could be up for a session with a jigsaw... work, family and recovery of leg permitting! Tim.

For clarity here is a sketch of the arch dropped 65mm - the vertical cuts make it work: |

|

|

Tim, I'm not a structural engineer but I think high stress occurs at that corner where there is a sudden change of direction in the arch. Also the arch must support rig tension (400lbs for a racing Enterprise) plus the weight of an adult. Hence Paul Fisher specified 100mm x 18mm ply for the arch. The glue joint is in compression on the inside but tension on the outside so the wood-glue bond may pull apart. In the diagram the upper section has a clockwise turning moment. The fillet gives the glue more "leverage" to prevent the upper section rotating clockwise, that reduces the tension on the wood-glue bond.....and of course it will be back to the 100x18 design spec. -Paul |

|

|

Point taken. A thought then. If the horizontal cuts where the deck beam drops down and rests on the uprights were actually angled down toward the outside slightly wouldn't that reduce the turning moment slightly so the weight of the deck pushing down would actually be locking the sides in. That might need a picture to make my point clearer.

Clearly the angled cut approach can work with the filler strip as well. A further option is to splint the joints with ply plates either side to distribute the load and lock the pieces together in all directions. Those plates could then be curved to distribute the roof load smoothly down into the upright. Again that could need a diagram. I'm not so quick at creating them for posting on line! Tim On 18 Mar 2013, at 16:12, adminHBBR [via UK HBBR Forum] wrote: The glue joint is in compression on the inside but tension on the outside so the wood-glue bond may pull apart. In the diagram the upper section has a clockwise turning moment. The fillet gives the glue more "leverage" to prevent the upper section rotating clockwise, that reduces the tension on the wood-glue bond.....and of course it will be back to the 100x18 design spec. |

|

|

Tim, You can just make out the overlapping splint joint in the picture below. The original hull frame was 6mm but Paul Fisher said make it at least 18mm like the arch - so I laminated 6+9+9 which interlocks with the 9+9 arch. As you can see another 6mm splint will fit neatly on the right. On the other side there is a diagonal overlap at 30 degrees.  It's a good job I never got past the undercoat in this hidden area - because it all has to come off! While I'm posting the case still leaves plenty of sleeping room for 2. Foot space is a little tight but rearranging the bunk sizes with one side for sleeping and the other side narrower for sitting will work well. The Euro standard curve (a saucer!) softens the edge and makes things safer in lumpy, bumpy weather....and when you get up in the middle of the night....   Nothing is glued yet, I'm testing all the clearances and operation first. Paul |

«

Return to General Discussion

|

1 view|%1 views

| Free forum by Nabble | Edit this page |